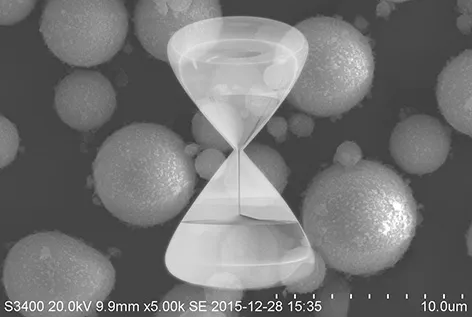

Spherical silicon micropowder is an inorganic non-metallic material with a mesh and flocculent quasi-particle structure. It possesses a small thermal expansion coefficient, low stress concentration, low friction coefficient, good corrosion resistance, excellent chemical stability, good dispersibility, and low thermal conductivity, among other properties. In recent years, it has gained attention in emerging fields such as aerospace and large-scale integrated circuit packaging. Thanks to its outstanding properties and broad application prospects, spherical silicon micropowder has become a research hotspot in the field of new materials.

There are various types of spherical silicon micropowder. The most common classification is based on the content of the radioactive element uranium (U), dividing it into low-radiation spherical silicon powder and general-purpose spherical silicon powder. Common preparation methods include the flame method, chemical precipitation method, gas-phase method, and plasma method.

Current Status of the Spherical Silicon Micropowder Industry

In the 1980s, Japan began developing spherical silicon micropowder, focusing primarily on the flame preparation method. By the early 2000s, Japan had achieved an annual production capacity of 10,000 tons. Spherical silicon micropowder has since been widely applied in large-scale integrated circuits, aerospace, and special materials manufacturing. Leading companies in this field include Shin-Etsu, Toshiba Melting, and Admatechs, which together account for approximately 70% of the global spherical silicon micropowder market. Notably, Admatechs has almost monopolized the market for spherical silicon micropowder with particle sizes below 1 µm.

American companies have developed products with high spheroidization rates, smooth surfaces, and excellent sphericity. They primarily use the high-temperature melt-spray spheroidization method, utilizing high-purity quartz as a raw material. At temperatures exceeding 2000°C, quartz is melted into liquid form, then sprayed and cooled to produce the finished product.

Due to the broad application prospects of spherical silicon micropowder in high-tech fields, foreign companies have implemented stringent technology barriers. Meanwhile, the development of spherical silicon micropowder technology in China is progressing rapidly. High-purity spherical silicon micropowder production in China is concentrated in areas such as Huzhou (Zhejiang) and Lianyungang (Jiangsu). In recent years, a few domestic companies, including Donghai Silica Micropowder, Zhejiang Huafei Electronics, and Jiangsu Lianrui New Materials, have collaborated with research institutions to overcome foreign technology blockades through extensive research and development. While notable breakthroughs have been achieved in production technology, gaps remain in product purity and particle size. Currently, domestically produced products account for only about 15% of the high-end market.

According to data from market research firm Mordor Intelligence, the global silicon micropowder market size was approximately USD 3.96 billion in 2021. It is projected to grow to USD 5.33 billion by 2027, with a compound annual growth rate (CAGR) of 5.1%.

Main Application Areas of Spherical Silicon Powder

01. Spherical Silicon Powder for Copper-Clad Laminates (CCL)

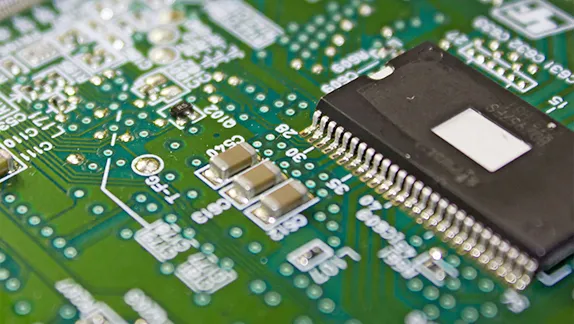

In recent years, inorganic filler technology has become a critical research focus for developing new products and enhancing the performance of copper-clad laminates. Due to its large surface area, spherical silicon powder can fully interact with epoxy resin, providing excellent dispersion ability. When dispersed in epoxy resin, it increases the contact area and bonding points, improving compatibility between the two materials. Additionally, spherical silicon powder offers superior mechanical and electrical properties, making it increasingly popular in the production of copper-clad laminates.

Currently, spherical silicon powder is primarily used in rigid CCLs, where it accounts for 20% to 30% of the total composition. Its use in flexible and paper-based CCLs is relatively limited.

02. Spherical Silicon Powder for Epoxy Molding Compounds (EMC)

More than 95% of microelectronic devices today use epoxy molding compounds. These compounds typically consist of fillers (60-90%), epoxy resin (less than 18%), curing agents (less than 9%), and additives (around 3%). The most commonly used fillers are silicon dioxide powders, which can constitute up to 90.5% of the compound. Silicon dioxide powder plays a crucial role in reducing the thermal expansion coefficient, increasing thermal conductivity, lowering the dielectric constant, enhancing environmental protection, achieving flame retardancy, reducing internal stress, preventing moisture absorption, strengthening molding compounds, and lowering the cost of packaging materials.

Requirements for Spherical Silicon Powder in EMC Applications:

1. High Purity

High purity is a fundamental requirement for materials used in electronic products, particularly in ultra-large-scale integrated circuits. In addition to minimizing conventional impurity elements, the content of radioactive elements must be as low as possible, ideally zero.

2. Ultrafine Particle Size and High Uniformity

The spherical silicon powder used for packaging ultra-large-scale integrated circuits abroad features fine particle sizes, narrow distribution ranges, and excellent uniformity. In the United States, the average particle size is typically 1-3 µm, while in Japan, it is generally 3-8 µm, with a maximum particle size of less than 24 µm.

3. High Spheroidization Rate and Dispersibility

A high spheroidization rate ensures the superior fluidity and dispersibility of fillers. High-quality spheroidization ensures that the product is fully dispersed in epoxy molding compounds, achieving optimal filling effects. Foreign products typically achieve a spheroidization rate of over 98%. In comparison, domestic materials generally achieve a spheroidization rate of around 90%, with a few reaching 95%.

03. Spherical Silicon Powder for Honeycomb Ceramics

Honeycomb ceramic carriers used for automobile exhaust purification and Diesel Particulate Filters (DPF) for diesel engine exhaust purification—primarily made of cordierite material—are produced using materials such as alumina, silicon powder, and others through processes like mixing, extrusion molding, drying, and sintering. Spherical silicon powder enhances the molding rate and stability of honeycomb ceramic products, contributing to improved product performance.

04. Paints and Coatings

Spherical silicon powder offers excellent performance in scratch resistance, leveling, transparency, and weather resistance, making it highly effective in coatings for various applications. These include decorative paints, wood paints, powder coatings, anti-corrosion coatings, and floor coatings.

05. Spherical Silicon Powder for Adhesives

Spherical silicon powder is used in adhesives for bonding wind turbine blades, building structural adhesives, and similar large composite structural components. It enhances the adhesive’s properties by providing suitable viscosity, excellent thixotropy, anti-sagging characteristics, high bonding strength, and fatigue resistance.

06. Cutting-Edge Application Fields

Spherical silicon powder is well-suited for reducing the viscosity of various resins and paints, improving fluidity, and minimizing burr formation. It is widely applied in advanced materials and additives, including:

- Fluidity enhancers and burr reducers for semiconductor packaging resins.

- Carbon powder additives.

- Silicone rubber fillers.

- Sintering materials and additives.

- Fillers for liquid packaging materials.

- Resin fillers and substrates.

- Applications in narrow-gap technologies.

Summary

In recent years, the rapid development of the electronic information industry has driven the demand for spherical silicon powder. It has become a key production material for copper-clad laminates and integrated circuits. By the end of the “14th Five-Year Plan,” it is expected that spherical silicon powder usage in copper-clad laminates will exceed 55%.

With stable chemical properties, excellent dispersibility, and environmentally friendly characteristics, spherical silicon powder has broad applications. It serves as a dispersant in the plastics and coatings industries, enhancing material surface finish. Additionally, its applications in aerospace, specialty plastics, high-end coatings, specialty fibers, rubbers, fine chemicals, and cosmetics continue to expand, showcasing its vast potential and promising future.