Dry grinding presents several safety concerns that need to be addressed to ensure a safe working environment. Here are the primary safety issues associated with dry grinding:

Safety Concerns in Dry Grinding

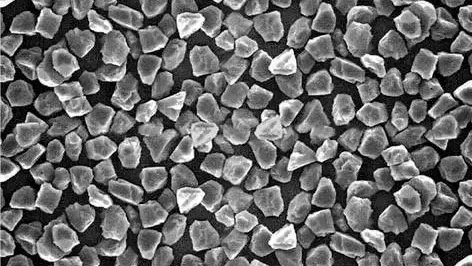

1. Dust Generation

Respiratory Hazards: Dry grinding produces significant amounts of dust, often containing respirable crystalline silica (RCS), which can lead to serious respiratory issues, including lung diseases and silicosis. Inhalation of this dust poses a long-term health risk for workers if proper dust control measures are not implemented.

Dust Control Systems: Effective extraction systems must be installed to capture airborne dust at the source. Without these systems, workers are at risk of exposure to harmful dust levels.

2. Fire and Explosion Risks

Sparks and Heat: The grinding process generates sparks and heat, which can ignite flammable materials present in the work area. This risk necessitates maintaining a clean workspace free of combustible materials and implementing appropriate fire suppression measures.

Material-Specific Risks: Certain materials, such as magnesium alloys, have a heightened risk of ignition during grinding, requiring additional precautions.

3. Eye Injuries

Flying Particles: The grinding process can produce flying debris and sparks that pose a risk of eye injuries. Workers must wear appropriate eye protection, such as safety goggles or face shields, to prevent injuries from particles or splashes.

4. Noise Exposure

Hearing Damage: Dry grinding can generate high noise levels that may lead to hearing damage over time. Workers should be provided with hearing protection to mitigate this risk.

5. Mechanical Hazards

Contact Injuries: Operators are at risk of abrasions or cuts from contact with the grinding wheel or workpiece. Proper training on safe operating procedures and the use of guards can help minimize these risks.

Wheel Breakage: Abrasive wheels can break during operation, posing a serious injury risk from flying fragments. Regular inspection and maintenance of grinding tools are essential to ensure their integrity.

6. Vibration Risks

Hand-Arm Vibration Syndrome (HAVS): Prolonged exposure to vibrations from grinding tools can lead to HAVS, which affects blood circulation and nerve function in the hands and arms. Implementing regular breaks and using anti-vibration gloves can help reduce this risk.

7. Chemical Exposure

Toxic Dust: Some grinding processes may involve materials that release toxic dust upon grinding, such as lead in certain resin-bonded wheels. Proper handling procedures and PPE are necessary to protect workers from harmful exposure.

Preventive Measures

To address these safety concerns effectively, several preventive measures should be implemented:

Dust Control: Install effective dust extraction systems and ensure they are functioning properly.

Personal Protective Equipment (PPE): Provide appropriate PPE, including respirators, safety goggles, gloves, and hearing protection.

Regular Maintenance: Conduct regular inspections of grinding equipment to prevent mechanical failures and ensure safety.

Training: Ensure that all operators are trained on safe operating procedures and the potential hazards associated with dry grinding.

Workspace Management: Maintain a clean work environment free of flammable materials and clutter.

Conclusion

By recognizing these safety concerns in dry grinding and implementing appropriate measures, workplaces can significantly reduce risks associated with dry grinding operations.