European Commission Vice President Maroš Šefčovič stated that by 2025, the European Union will be able to produce enough batteries to power its rapidly growing electric vehicles. So this will eliminate the need to rely on imported batteries.

As part of its plan achieve “climate neutrality” by 2050, the EU aims to increase local production in green industries. It includes hydrogen fuel for low-carbon steel production, and batteries for new energy vehicles.

Currently, about 80% of the world’s lithium-ion battery production is in China. But according to the EU’s plan, Europe’s lithium-ion battery production capacity will expand rapidly.

There are currently 15 large battery factories under construction in Europe, including Swedish company Northvolt’s factories in Sweden and Germany, Chinese battery manufacturer CATL’s factories in Germany, and South Korean company SK Innovation’s second factory in Hungary.

The European Commission expects that by 2025, there will be 13 million low-emission cars on European roads, requiring further investment.

1. Cathode Materials

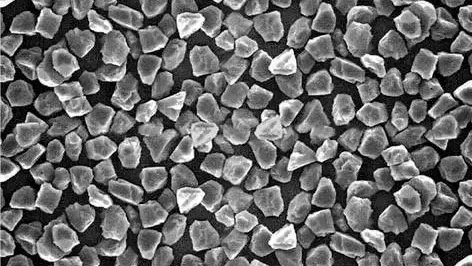

Lithium Cobalt Oxide (LiCoO₂)

Features: It has a high energy density, allowing it to store more electricity in the battery. Its discharge platform is stable, and the voltage output remains relatively consistent, which ensures a stable power supply for the device during use. For example, it is widely used in 3C electronic products, such as early smartphones.

Application scenario: Lithium-ion batteries primarily used for small electronic devices like mobile phones and laptops. However, due to the scarcity of cobalt resources, large price fluctuations, and certain environmental and safety risks, its use in large-scale battery fields (e.g., electric vehicles) is limited.

Lithium Nickel Manganese Cobalt Oxide (NMC, LiNiₓMnₓCo₁ – ₂ₓO₂)

Features: By adjusting the ratio of nickel (Ni), manganese (Mn), and cobalt (Co), the battery’s energy density, cycle life, and safety can be balanced. For example, higher nickel content increases energy density, while adding manganese helps improve the battery’s safety and stability.

Application scenarios: Widely used in electric vehicles and energy storage systems. For example, models like the Tesla Model 3 use NMC batteries, which meet the long-range requirements for electric vehicles while also ensuring battery safety and longevity.

Lithium Iron Phosphate (LiFePO₄)

Features: It offers good thermal stability, making it relatively safe in high-temperature environments and less prone to dangerous situations like thermal runaway. It also has a long cycle life, with slower capacity decay after multiple charges and discharges. However, its energy density is relatively low, meaning it may not store as much electricity as some other cathode materials of the same volume or weight.

Application scenarios: Due to its high safety and long cycle life, it is widely used in applications that require these attributes, such as electric buses and energy storage power stations. For example, some of BYD’s electric buses use lithium iron phosphate batteries, providing a safe and reliable energy solution for urban public transportation.

Lithium Manganese Oxide (LiMn₂O₄)

Features: It has a low cost, abundant resources, and a relatively simple manufacturing process, making it cost-effective. It also has high-rate performance, capable of large current charging and discharging in a short time, making it suitable for scenarios that require fast charging or high power output. However, its cycle life and high-temperature performance are relatively poor.

Application scenarios: Commonly used in power tools, light electric vehicles, and other equipment that is cost-sensitive and has specific requirements for battery rate performance.

2. Anode Materials

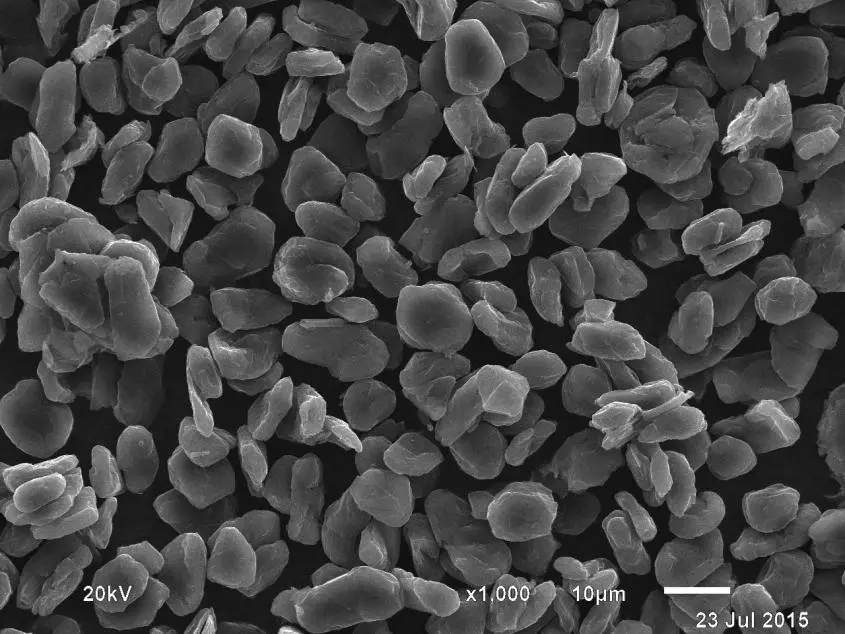

Graphite

Features: Graphite includes both natural and artificial varieties. It has good conductivity and a layered structure, which provides efficient insertion and extraction channels for lithium ions, allowing the battery’s charging and discharging processes to proceed smoothly. Additionally, graphite materials have good chemical stability and can maintain relatively stable performance in the battery’s operating environment.

Application scenarios: Graphite is the most widely used anode material, commonly found in various lithium-ion batteries, ranging from mobile phone batteries to electric vehicle batteries.

Silicon-based Materials

Features: Silicon has an extremely high theoretical specific capacity. It can store more lithium ions than graphite, significantly improving the battery’s energy density. However, silicon undergoes large volume changes during the charging and discharging process. This can lead to the powdering and shedding of electrode materials, thereby affecting the battery’s cycle life and performance stability.

Application scenarios: With continuous technological advancements, the application of silicon-based materials in high-performance lithium-ion batteries has gained attention. Research institutions and companies are working on developing silicon-carbon composite anode materials for next-generation, high-energy-density batteries. They’re expected to be widely used in future electric vehicles and high-end electronic devices.

Lithium Titanate (Li₄Ti₅O₁₂)

Features: Lithium titanate is a zero-strain material. During the process of lithium-ion insertion and extraction, the electrode material’s volume hardly changes, providing excellent cycle life and the ability to withstand multiple charge and discharge cycles. It also has high safety and good rate performance, allowing for fast charging and discharging. However, its energy density is relatively low.

Application scenarios: It is mainly used in applications that require high battery life and safety, such as energy storage systems and specialized electric vehicles.

3. Electrolyte

Organic Carbonates

Features: Commonly used organic carbonates, such as ethylene carbonate (EC) and propylene carbonate (PC). They have good solubility and can fully dissolve lithium salts, ensuring that the electrolyte has high ionic conductivity. These carbonates also have good electrochemical stability and remain stable within the battery’s operating voltage range. And they’re without decomposing or reacting in ways that affect battery performance.

Application scenarios: Organic carbonates are the main component of lithium-ion battery electrolytes and are widely used in various types of lithium-ion batteries.

Lithium Salts

Features: Lithium hexafluorophosphate (LiPF₆) is the most commonly used lithium salt. It provides lithium ions in the electrolyte and has good ionic conductivity in suitable organic solvents. However, it is sensitive to moisture and easily decomposes when exposed to water, so moisture levels must be carefully controlled during battery production and usage.

Application scenarios: As a key component in the electrolyte, lithium salts are used to prepare electrolytes for various lithium-ion batteries. And they’re essential for ensuring the battery’s proper operation.

4. Diaphragm Materials

Polyolefins (such as Polyethylene PE, Polypropylene PP)

Features: Polyolefins have good mechanical properties and can withstand the internal pressure of the battery. It preventes direct contact between the positive and negative electrodes, which could cause a short circuit. They also have good wettability with the electrolyte. This ensures proper penetration of the electrolyte in the separator and providing a channel for lithium-ion transmission. Moreover, polyolefins exhibit good chemical stability and are not prone to reacting with other materials in the battery.

Application scenarios: Polyolefins are the main materials used in lithium-ion battery separators. It plays a vital role in ensuring both the safety and performance of various lithium-ion battery products.