Jet milling is a highly effective method for particle size reduction, widely used across various industries, including pharmaceuticals, food, and chemicals. Here are the key advantages of jet milling:

Advantages of Jet Milling

1. Low Grinding Temperature

Jet mills operate without generating significant heat, making them ideal for grinding heat-sensitive materials. The adiabatic expansion of gas during the milling process helps maintain low temperatures, preventing degradation of sensitive compounds.

2. High Efficiency and Fine Particle Size

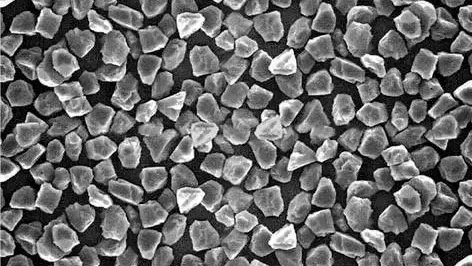

Jet milling can achieve very fine particle sizes, typically in the range of 1 to 10 microns, with some applications reaching down to 200 nanometers. This capability is crucial for industries where particle size directly affects product performance, such as in pharmaceuticals where increased surface area can enhance solubility and bioavailability.

3. Narrow Particle Size Distribution

The process yields a narrow particle size distribution, which is essential for applications requiring uniformity. This precision helps ensure consistent product quality across batches.

4. Contamination-Free Operation

Jet mills do not have moving parts in the grinding chamber, significantly reducing the risk of contamination from wear and tear. The closed-loop design further minimizes exposure to external contaminants, making it suitable for high-purity applications like pharmaceuticals.

5. Versatility

Jet milling can handle a wide variety of materials, including brittle, hard, and abrasive substances. It is suitable for both dry and wet milling applications, allowing for flexibility in processing different types of materials.

6. Scalability

The technology is easily scalable from laboratory to production levels. This scalability makes jet milling a practical choice for companies looking to expand their operations without changing their milling technology.

7. Reduced Risk of Degradation

Due to its low-temperature operation and minimal mechanical impact, jet milling reduces the risk of degradation in sensitive materials. This characteristic is particularly beneficial in pharmaceutical manufacturing, where maintaining drug stability is critical.

8. Simultaneous Drying and Milling

Jet mills can perform drying operations concurrently with grinding, which can streamline processes and reduce production time.

In summary, jet milling offers numerous advantages that make it an attractive option for many industries focused on producing high-quality powders with precise specifications while minimizing contamination risks and operational costs.