Calcium carbonate is a common inorganic compound that widely exists in nature. It is widely used in various industrial fields due to its diverse physical and chemical properties. Among them, activated calcium carbonate and light calcium carbonate are two important calcium carbonate products. They have significant differences in production technology, physical properties and application fields.

Production process

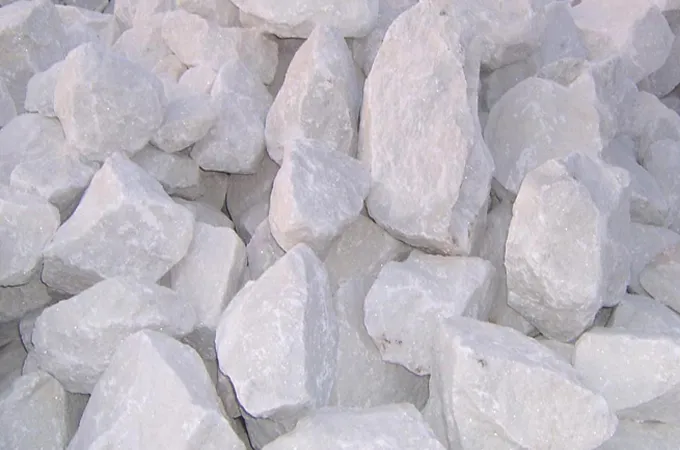

Activated calcium carbonate is mainly produced by physical methods. Its production process usually uses high-purity limestone (such as calcite, chalk, etc.) as raw materials. It’s refined by physical means such as grinding. The surface of the ground calcium carbonate particles is treated by adding activators. Usually there are phthalate coupling agents, stearic acid and lignin, etc. So it can form a special cladding structure on the surface. In this case it improves its dispersibility and affinity in the polymer matrix. Light calcium carbonate is produced by chemical methods. Its production process involves calcining raw materials such as limestone to produce lime and carbon dioxide. Then adding water to digest the lime to produce calcium hydroxide emulsion, then introducing carbon dioxide for carbonization reaction. That’s the way to produce calcium carbonate precipitation. After dehydration, drying and crushing, this precipitate can be obtained as a light calcium carbonate product.

Physical properties

Activated calcium carbonate has irregular particle shapes and is a polydisperse powder with a wide particle size distribution. The average particle size is generally between 5-10 microns. Due to the activation treatment, its surface properties are improved, it has strong hydrophobicity, high whiteness, good fluidity, and uniform dispersion. The particle shape of light calcium carbonate is relatively regular and can be regarded as a monodisperse powder. Its particle size can be very fine, such as ultrafine calcium, microfine calcium, nano calcium, etc. The whiteness of light calcium carbonate is generally very high, the standard is usually above 90, and the sedimentation volume is relatively high, generally above 2.5. Its average particle size is generally 1-3 microns, and the particle size distribution is narrow.

Application areas

Uses of activated calcium carbonate

With its excellent dispersion and affinity, it has shown wide application value in many industrial fields. Specifically, it is often used as:

1. High-end filler: In industries such as rubber, plastics, plastic steel doors and windows, PVC cable materials, pipes, tires, shoe soles, polyethylene blown film, sealing strips, fiberglass products, cable packaging cloth and other industries, activated calcium carbonate is used as a filler. It can not only increase the volume of products and reduce costs, but also significantly improve the dimensional stability, hardness and stiffness of products, and improve processing performance and heat resistance.

2. Fillers and coating agents in the papermaking industry: In the papermaking process, activated calcium carbonate can be used as fillers and coating agents to improve the gloss of the paper, enhance the hardness of the paper, and make the paper more durable.

3. Extensive pigments in the coating industry: In coatings, activated calcium carbonate is used as a filler to act as a skeleton and improve the wear resistance, corrosion resistance and gloss of the coating. At the same time, it can also reduce the viscosity of the coating, increase the solid filling amount, lower the baking temperature, and shorten the baking time, thereby improving the production efficiency and product quality of the coating.

4. Dispersants and stabilizers in the ink industry: In inks, the dispersion and stability of activated calcium carbonate help improve the printing effect and gloss of the ink.

Uses of Light Calcium Carbonate

Light calcium carbonate plays an important role in many fields with its high whiteness, high purity, high scattering coefficient and stable pH value. Specifically, it is often used as:

1. Filler and thickener: In rubber, plastic and coating, light calcium carbonate as a filler can reduce costs, reduce material weight, and improve the hardness and wear resistance of products. In food and medicine, it can also be used as a thickener to increase the viscosity and consistency of products.

2. Coating agent and filter material in the papermaking industry: In the papermaking process, light calcium carbonate can be used as a coating agent and filter material to increase the hardness and opacity of paper while reducing papermaking costs.

3. Feed additive: In feed, light calcium carbonate can provide the calcium and phosphorus required by animals, which helps the growth and development of animals.

4. Pharmaceutical and oral care products: In the pharmaceutical field, light calcium carbonate can be used as a calcium supplement to prevent and treat osteoporosis. At the same time, it can also be used to make oral care products such as toothpaste and chewing gum, as well as orthopedic medical materials such as artificial bones and dental filling materials.

5. Additives in the construction field: In the construction industry, light calcium carbonate can be used as an additive to building materials to make lightweight concrete, thermal insulation materials, etc., to reduce the density of building materials, improve thermal insulation performance, and reduce the cost of building materials.