In recent years, advancements in non-metallic mineral processing have shifted. It’s from merely using fillers for structural purposes to enhancing functionality like hardness, hiding power, and resistance to corrosion and heat. As a result, the use of non-metallic mineral fillers in coatings has gained more attention. This article mainly introduces the six reasons to add kaolin to coating products, highlighting why it is a preferred filler.

Four basic components of coatings

Four components include film-forming substances (resins, emulsions), pigments (including body pigments), solvents, and additives (auxiliaries). Among these, pigments in coatings primarily provide color and hiding power. Pigments can be divided into coloring pigments and body pigments. The former is mainly responsible for color performance, while body pigments, also known as fillers, are used to improve the thickness and functionality of the coating. Non-metallic mineral powders, such as kaolin, are mostly used as body pigments in coatings.

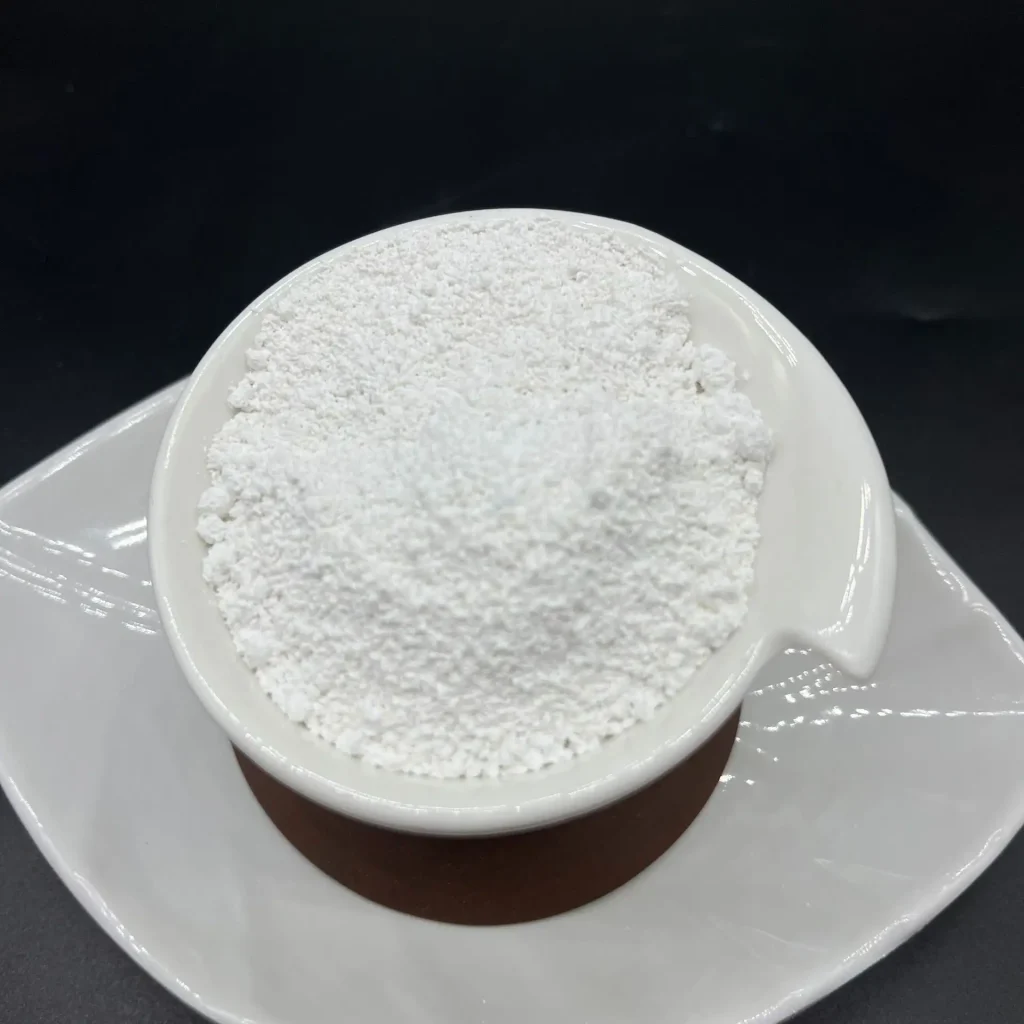

What is Kaolin?

Kaolin is an inorganic silicate with crystal water. It is soft, greasy, and easy to disperse in water. Kaolin-based pigments have the ability to improve performance without sacrificing hiding power, gloss, pencil hardness, flexibility, and other properties.

According to different processing techniques, kaolin is divided into two categories: washed kaolin and calcined kaolin. Washed kaolin has lower whiteness and is generally used in latex paint to improve construction performance. After high-temperature calcination, the whiteness of calcined kaolin is greatly improved, and the particle size is fine. It has excellent suspension and dry film hiding power. It is one of the best extenders for titanium dioxide. Therefore, it can resist precipitation, increase dry film hiding power, and reduce the amount of titanium dioxide in latex paint.

However, due to the large oil absorption of calcined kaolin, excessive addition will significantly impact the washability of the coating. Additionally, due to its acidic nature, low impurity content, and good chemical stability, calcined kaolin is compatible with the acidic environment of the cathode electrophoretic tank, making it the preferred filler for cathode electrophoretic coatings.

The six main functions of kaolin in coatings

Improve the hiding power of coatings

Kaolin added to coatings at a certain ratio can improve the hiding power of coatings, reduce light transmittance, and make coatings more uniform and smooth. Kaolin additives have been used to extend many types of pigments in almost all types of water-based and solvent-based coatings. Engineer Chen started with the selection of mineral sources, processing methods, and formula improvements. He conducts a series of experiments using kaolin and calcium carbonate to replace 15% of titanium dioxide in water-based coatings. The final results showed that, across a wide range of comparative pigment volume concentrations, the hiding power of the coating system remained essentially unchanged. This is the case when kaolin replaced 15% of titanium dioxide. At the same dosage, kaolin exhibited better hiding power than calcium carbonate.

Enhance the hardness and durability of coatings

Kaolin can also act as a filler and enhancer in coatings. Due to its fine particles and strong structural stability, kaolin can reduce the expansion coefficient of coatings and increase their hardness and durability. Therefore, kaolin is widely used in decorative and industrial coatings that require durability and toughness.

Improve the reflectivity and color intensity of coatings

Kaolin is hydrophilic, making it easy to disperse, with a small particle bulk density and good suspension performance. It can maximize the ability to reflect light and produce better reflection effects, thereby changing the gloss of the coating. By adding an appropriate amount of kaolin, the coating can present a matte effect, enhancing its decorative properties. This results in coatings with better gloss and brighter colors. The American Engelhard Company once replaced 17% of phenol green pigment and 14% of titanium dioxide with a bright fine-grained kaolin product, resulting in a coating with high reflectivity and color intensity. This is because the kaolin particles improve the spacing between the pigment particles.

Improve coating ability and anti-dripping property

Kaolin is also widely used as a thickener in the coating industry. Due to its water absorption and gelling properties, kaolin can absorb the solvent in the coating and form a gel-like structure. This gel-like structure can increase the viscosity of the coating and prevent the separation of pigments and solvents. The thickening effect of kaolin improves the coating ability and anti-dripping properties, making the coating easier to apply and use.

Improve the stability of the coating

Due to its fine particles and high specific surface area, kaolin can increase the volume of the coating and improve its fluidity and dispersibility. It acts as a stabilizing dispersant and anti-settling agent in coatings. The stabilizing dispersant effect of kaolin can maintain the color and texture stability of the coating and extend its service life. The anti-settling agent effect of kaolin can prevent unevenness and stratification during long-term storage, thereby improving the stability of the coating product.

Reduce costs

As a filler, adding a certain amount of kaolin to paint can replace expensive titanium dioxide and improve the hiding power of the paint. One company replaced 8-10% of various pigments in a building alkyd paint with a high-brightness fine-grained kaolin additive, and the paint performance remained almost unchanged.

Application of kaolin in coatings

Kaolin is commonly used in architectural coatings, such as interior and exterior wall coatings, wood coatings, and floor coatings, providing buildings with a beautiful and durable protective layer.

In the field of industrial coatings, kaolin can enhance the performance of coatings in products such as automotive coatings, anti-corrosion coatings, and powder coatings. It can meet the requirements of various industrial environments.

In the ink industry, kaolin can improve the gloss, hiding power, and stability of inks, making printed products clearer and more vivid. High-quality calcined kaolin is widely used in special functional coatings, such as anti-corrosion coatings, heat-resistant coatings, insulation coatings, waterproof coatings, and radiation-proof coatings.

If you have some further questions, please contact the engineers of Epic Powder for the best mill to produce kaolin.