Air jet mill is a widely used powder processing technology. It achieves fine grinding of materials through the impact and friction effect of high-speed airflow. It has the advantages of wide range of particle size control, high production capacity, low energy consumption, simple operation, etc. And it’s suitable for fine grinding of various materials. In future, with the improvement of science and technology, airflow mill has great potential in particle control and nano-powder processing.

As an emerging technology application, air jet grinding has attracted widespread attention. It emerged because some technical difficulties in the process of grinding, such as thermal damage, abrasive wear and surface quality. Air jet grinding uses high-speed airflow to drive the abrasive in the airflow, thereby achieving efficient grinding. Due to its unique working method, air jet grinding has many advantages. Such as low temperature, no contact, high precision and environmental protection. In future, jet milling is expected to become an important technology in material grinding. And it will play an important role in industrial applications.

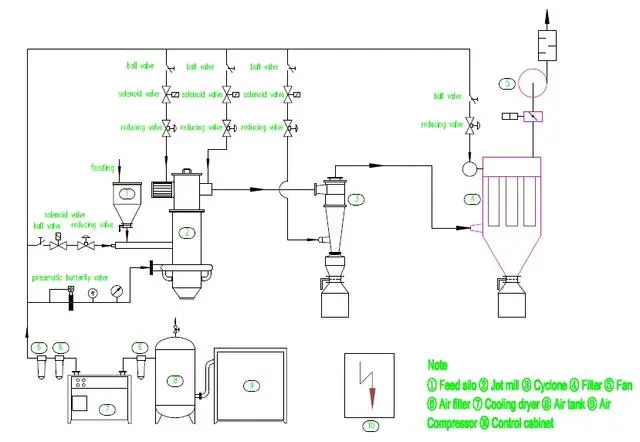

Application site of jet mill

Working principle of air jet mill

Air jet mill is a new technology that uses high-speed airflow to grind the surface of an object. Its core principle is to use the air entrapment effect. Small particles are directly impacted onto the surface of the workpiece through high-speed airflow to achieve the grinding effect. Air jet mill has the advantages of uniform distribution of abrasive, high processing accuracy, and no surface fracture or defect. It will have a wider application prospect in the future.

Air jet mill working process diagram

Components of air jet mill

Air jet mill is a powder grinding technology that consists of several major components. The most important one is the grinding chamber. It is the core of the entire air jet mill. There is a rotating rotor in the grinding chamber with multiple grinding rollers mounted on it. In the grinding chamber, the powder enters through the jet and collides with the rotating grinding rollers to produce high-speed airflow. This process causes it to be continuously impacted, ground and crushed. The jet mill also includes an airflow sorting system, which can separate and collect the powder according to particle size.

The operation of the entire air jet mill depends on the fluidity and dispersibility of the powder material, so by adjusting parameters such as feed rate, grinding roller speed and air flow rate, the size and distribution of the ground particles can be controlled. The components of the air jet mill work closely together to provide an efficient, precise and repeatable powder grinding process. With the development of technology, air jet mills are expected to play a more important role in the preparation of nanomaterials and the powder industry.

There are some key technical details in the working principle that need to be explained. First, the jet speed and pressure of the air jet mill need to be precisely controlled to ensure that the abrasive particles can fully collide and rub the material surface. Secondly, the choice of abrasive for air jet mill is also very important. Usually, materials with high hardness and uniform particles are selected to achieve better grinding effect. In addition, the air jet mill also needs to consider the inlet and outlet speeds of the material to control the residence time and grinding effect of the material. In general, air jet mill is an efficient and fine grinding technology, which is expected to be more widely used in the field in the future.

Application fields of jet mill

Chemical industry

1. Refinement and improvement of catalysts

Jet mill technology has a wide range of applications in the chemical industry, one of which is the refinement and improvement of catalysts. Catalysts play a vital role in chemical processes, and optimization of their performance can significantly improve reaction efficiency and product quality. The airflow mill can micronize the catalyst through the action of high-speed airflow, making the particle size more uniform and finer, increasing the surface area and reaction rate of the reaction. In addition, jet mill can also effectively change the physical and chemical properties of the catalyst, such as thermal stability, activity, etc., thereby further improving its catalytic performance. In the future, as the chemical industry’s requirements for catalyst quality continue to increase, jet mill technology is expected to become an important tool, providing more options and possibilities for catalyst R&D and production.

2. Preparation and optimization of granular materials

As an efficient technology for grinding and pulverizing granular materials, jet mill is widely used in the chemical industry. It can be used for the preparation and optimization of granular materials to achieve fine control of particle size and shape by adjusting parameters such as air flow speed and material feed volume. Due to the unique grinding mechanism and high-speed flow characteristics of the airflow mill, it can effectively break fine particles and reduce energy consumption.

In addition, the jet mill also has the advantages of good diffusion and dispersion effect, easy cleaning and maintenance, and can be used in processes such as granular material preparation, powder mixing and refining in the chemical industry. In the future, with the further development of chemical processes and the increasing requirements for product quality, jet mills are expected to play a wider role in the chemical industry and provide more solutions for the preparation and optimization of granular materials.

Air compressor for jet mill

Advantages of air jet mill

Advantage of controllable particle size

The air jet mill has the advantage of controllable particle size. By adjusting the air velocity and the feed amount, the particle size of the final product can be precisely controlled. It makes jet mill widely used in various fields, such as fly ash treatment, chemical material production and food processing. In addition, the air jet mill can also process materials of various particle sizes. It has good adaptability to materials with high hardness and viscosity. Therefore, the air jet mill is considered to be an efficient, flexible and controllable pulverization technology with great development potential.

Characteristics of low energy consumption and high efficiency

Compared with traditional mechanical grinding equipment, air jet mills have the characteristics of low energy consumption and high efficiency. Due to fewer wear parts, the maintenance cost of air jet mills is also greatly reduced. In addition, air jet mills can also achieve dust-free and noise-free environmentally friendly operation. This aspect makes them a more superior grinding equipment.

Advantages for a variety of materials

As a toolless grinding technology, air jet mills have many advantages in processing a variety of materials. Compared with traditional grinding methods, air jet mills do not leave additional heat and stress effects on the surface of the material, which can reduce the risk of material deformation and cracks. In addition, they have high processing accuracy and high efficiency, and can also process various materials, such as metals, ceramics, glass, etc. These advantages make air jet mills one of the key technologies in the field of material processing, and their application prospects are worth looking forward to.

Contamination-free and easy-to-clean properties

Jet mills are pollution-free and easy to clean. Because jet milling is a dry grinding technology that does not require the use of liquid media or solvents, there is no waste water, liquid waste or air emissions. This makes jet grinding an environmentally friendly grinding process. Plus, cleaning becomes easier. Since no liquid lubricants or coolants are used, the exterior of the unit needs to be simply cleaned. This not only improves production efficiency but also reduces the time and cost required in the cleaning process. Therefore, airflow mills have significant advantages in being pollution-free and easy to clean.

Good operational flexibility

The airflow mill has good operational flexibility, which is one of its major advantages. Since there is almost no contact between the abrasive and the material in the airflow mill, the problem of abrasive contamination of the material can be avoided. In addition, the airflow mill can also adjust the feed speed, abrasive particle size and air flow speed as needed, thereby achieving fine control and adjustment to meet different process requirements. This operational flexibility makes jet mills widely used in a variety of industrial fields, such as mining, chemical industry, food, etc. In the future, with the continuous advancement of technology, the operational flexibility of airflow mills is expected to be further improved, providing more efficient and precise grinding solutions for various industries.

Airflow mill equipment and maintenance cost

As an advanced powder processing technology, airflow mill has a wide range of technical applications and many advantages. However, it also has some challenges and limitations. First, the purchase and maintenance costs of airflow mill equipment are high, and the capital investment requirements are large. Secondly, due to the high-speed rotation of the equipment and the collision and friction of the powder particles, the equipment is susceptible to wear and tear, and regular maintenance and replacement of parts are required, which increases the operating cost. In addition, maintenance personnel need to have professional knowledge and skills to ensure the normal operation of the equipment. In the future, with the development of technology and the intensification of market competition, it is expected that the cost and maintenance efficiency of airflow mill equipment will be further improved, promoting the widespread promotion and development of its application.

Strict requirements for raw material properties

As an emerging powder processing technology, airflow mill faces some challenges and limitations in its application. Among them, strict requirements for raw material properties are an important aspect. Airflow mills have very strict requirements on the particle size, shape, density, etc. of raw materials. The uniformity and stability of raw materials have a direct impact on the effect of airflow mills. In addition, for some raw materials with special properties, such as flammable and explosive, the use of airflow mills also requires special safety measures. Therefore, when using airflow mills, strict requirements on raw material properties become a limiting factor that cannot be ignored. Nevertheless, as technology continues to develop and improve, it is believed that the efforts of air jet mills in overcoming these challenges and limitations will achieve greater breakthroughs, bringing broader application prospects to more industries.

Dust generation and dust control during processing

As an advanced processing technology, air jet mills face some challenges and limitations. One of the main issues is the control of the large amount of dust and particles generated during processing. Due to the high speed and high pressure characteristics of air jet mills, a large amount of fine particles and dust will be generated during processing, posing potential risks to the environment and the health of operators. Therefore, manufacturers and users need to take effective measures to control and reduce dust emissions. At present, some methods have been developed, such as building closed systems, using dust collectors and screening devices. These methods are to improve dust control. However, jet mills still face some challenges in dust control, further research and technical improvements are needed to improve it.

Future prospects of air jet mills

In the future, air jet mills will continue to make technical improvements and innovations. First, the selection and performance of grinding agents will be improved to achieve higher crushing efficiency and better particle size control. Secondly, the equipment and process of air jet mills will be further optimized to improve operational stability and energy efficiency. Thirdly, according to the needs of different industries, more customized jet mill will meet the processing requirements of specific materials. Also, with the development of AI and automation technology, the intelligence level of air jet mill equipment will be improved. This will realize automatic control and remote monitoring. In short, air jet mill has broad application prospects and market development space. It will continue to be one of the important technologies in the field of particle crushing in the future.

As an emerging powder processing technology, airflow mills have broad application prospects and great value. By adjusting the speed, pressure and direction of the airflow, the fine processing and classifying of materials can be achieved. It’s a high-efficiency energy consumption and high-quality production process. Compared with traditional mechanical grinding technology, airflow mills have the advantages of dust-free, noise-free and pollution-free. They are suitable for processing fine materials such as medicines, cosmetics, food, etc. As people’s requirements for quality and environmental protection continue to increase, the usages of airflow mills will become more extensive. In the future, air jet mill will play a greater role in the powder processing industry. It will bring more convenience and benefits to people’s lives and industrial production.