At present, in the mining industry, large ball mills have achieved benefits such as extended service life and reduced energy consumption through the implementation of variable frequency speed regulation. In light of the increasing environmental pressures in the cement industry, this sector has begun to focus on energy conservation and consumption reduction. Is it feasible to transfer this technology to the cement grinding system? The report addresses this question from four aspects: research background, research plan, research results and conclusions, and industrial experimental results and conclusions related to ball mill grinding effect.

I. Research Background

1. Ball Mill

Application Field: Due to its simple structure and strong reliability, the ball mill is widely used in metallurgy, the chemical industry, cement, ceramics, construction, and other major fields.

Advantages: It features a simple structure, high reliability, and easy maintenance. In the field of cement grinding, its contribution to the particle distribution and particle shape makes it an essential piece of equipment in the cement grinding process.

Trend: In the current cement industry, coal grinding and raw material crushing have shifted from ball mills to a combination of roller press semi-final grinding and ball mills. The ball mill plays an irreplaceable role in cement performance. Therefore, it remains a mainstream component of the cement grinding system. Even as equipment sizes increase, the ball mill continues to hold an important position in the cement grinding system, both now and in the future.

Energy Utilization: In terms of energy conversion, the ball mill transforms part of the input energy into surface energy of the solid, while the rest is dissipated as heat and sound energy. Consequently, the energy utilization rate of the ball mill is relatively low.

2. Speed

The speed of the ball mill is fixed and based on the theory that the grinding body in the mill has a maximum drop height, which guides the impact crushing effect. However, for optimizing the grinding effect of the ball mill in the current cement grinding system, determining the optimal speed is still worth further discussion. In previous grinding systems, the filling rate directly affected the movement state of the medium in the ball mill. Thus, focusing on grinding also necessitates a re-evaluation of the appropriate filling rate.

3. Filling Rate

In the actual grinding process, the filling rate directly affects the movement state of the medium inside the ball mill. The impact of speed on the grinding effect at different filling rates is also worth further study.

II. Establish a Suitable Evaluation Method

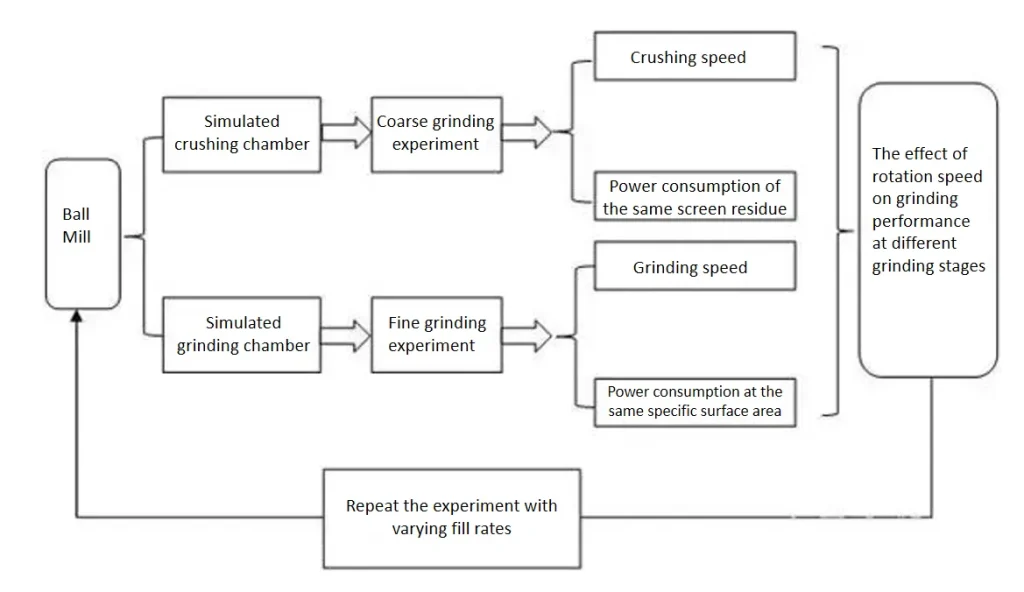

The report is divided into four parts: establishing a suitable evaluation method (considering crushing effect, grinding effect, and power consumption level to achieve the same crushing/grinding effect); designing experiments to study the influence of ball mill speed and filling rate on crushing effect and grinding effect; examining the medium motion state at different speeds and filling rates using a ball mill with a transparent plexiglass end cap; and analyzing and explaining the experimental results using medium motion theory.

1. Evaluation Method

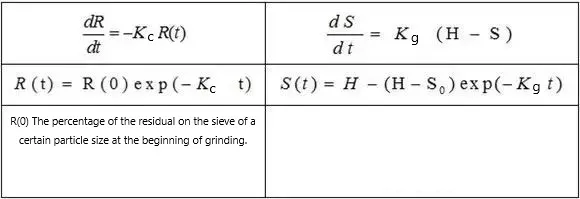

The evaluation method is based on the model of grinding dynamics.

Crushing Speed: This is defined as the rate of change in the percentage of coarse particles over time. During the grinding process, the rate of reduction of particles of a certain size is proportional to the content of particles of that size in the material. Using this concept, a grinding dynamics equation has been developed: the rate of change of the specific surface area (S) of the material over time. It is assumed that this rate of change is proportional to the difference between the current specific surface area of the material and the target specific surface area (H). In other words, during the ball mill grinding process, the rate of change of the specific surface area (S) over time is used to evaluate grinding speed.

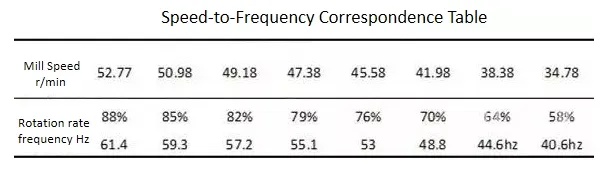

Current Setup: Most ball mills still have two chambers even after semi-final grinding by roller press. The first chamber is for coarse grinding, and the second chamber is for fine grinding. Wu Xiaomei installed a frequency converter on a small mill in the laboratory to simulate the two chambers of a large ball mill and study the effect of different rotation rates on crushing speed and grinding speed. She also theoretically calculated the energy consumption levels corresponding to different rotation rates needed to achieve the same crushing effect and the same specific surface area.

Research Scheme Design

2. Experiment Design

During the experiment, two filling rate boundary conditions were set, and test parameters were established on the small test mill. The gradation of the grinding body was studied within the speed range of 58% to 88%. The gradation of the grinding body was based on that of the large mill. For simulating the coarse grinding test, the gradation used was that of the second chamber (head bin) of the ball mill, as shown in the figure. Material was first taken from the head bin and crushed in the laboratory crusher. The strength of the material in the second bin is approximately 1% of the screen residue.

2.1 Effect of rotation speed on grinding effect when filling rate is 18%

2.1.1 Coarse Grinding Experiment

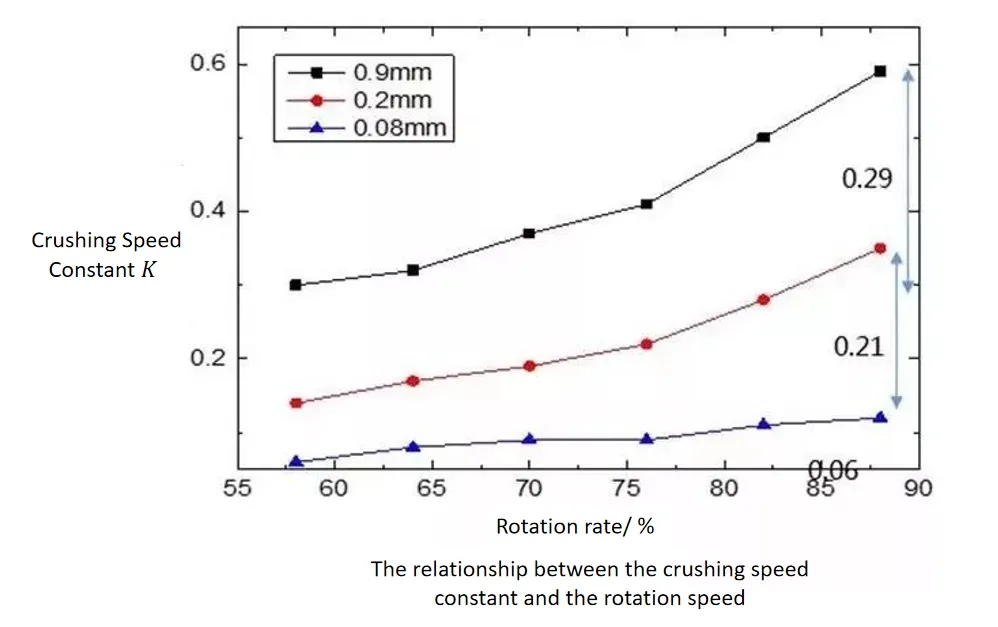

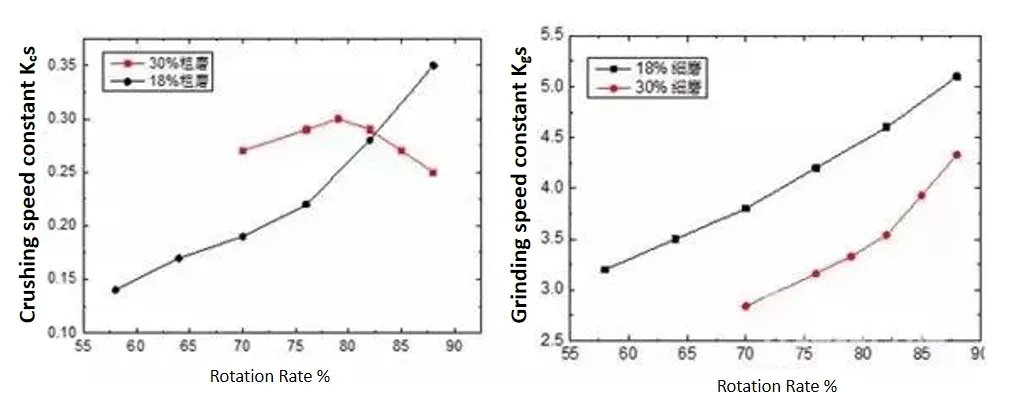

2.1.1.1 Relationship Between Rotation Rate and Crushing Speed Constant

The relationship between rotation rate and crushing speed constant is illustrated in the figure. It shows that the screen residue value decreases as the rotation rate increases. For example, 0.9 mm K break > 0.2 mm K break > 0.08 mm K break; the crushing speed of fine particles is less sensitive to changes in rotation speed compared to that of coarse particles.

2.1.1.2 Relationship Between Rotation Rate and Crushing Energy Consumption

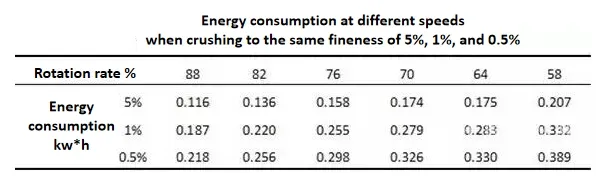

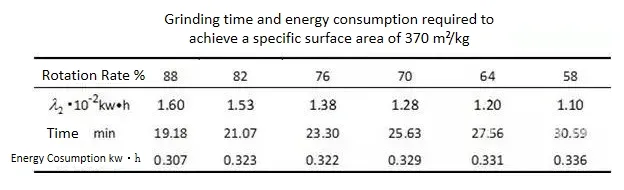

From the study of the relationship between rotation rate and crushing energy consumption (as shown in the figure below), we observe that as the rotation rate increases, the constant of crushing energy consumption also increases.

Energy Consumption at Different Rotation Speeds: When achieving the same screen residue, energy consumption varies with different rotation speeds. At a filling rate of 18%, as the rotation speed increases from 58% to 88%, the energy consumption for achieving the same fineness decreases. Additionally, the smaller the target fineness, the greater the difference in energy consumption between different rotation speeds.

2.1.2 Fine Grinding Experiment

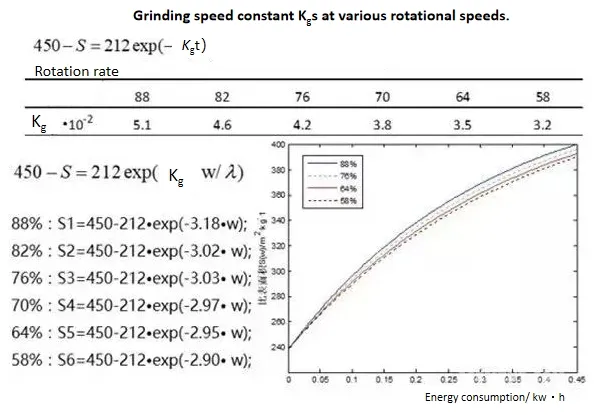

2.1.2.1 Relationship Between Rotation Rate and Material Grinding Speed Constant

As the rotation rate increases, the grinding speed constant also increases, indicating improved grinding effect. By incorporating the energy parameter into the equation, we determine the relationship between the specific surface area and grinding speed.

2.1.2.2 Relationship Between Rotation Rate and Grinding Energy Consumption

When the filling rate is 18%, as the rotation rate increases from 58% to 88%, the grinding energy consumption required to achieve the same specific surface area decreases. The difference in energy consumption between different rotation rates becomes more significant as the target specific surface area increases.

2.2 Effect of Rotation Speed on Grinding Effect at a Filling Rate of 30%

2.2.1 Coarse Grinding Experiment

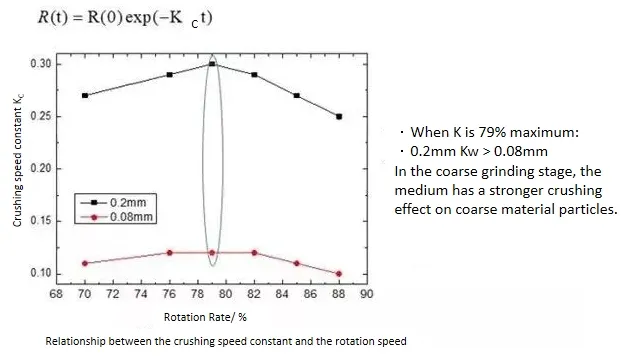

2.2.1.1 Relationship Between Rotation Speed and Crushing Speed

The value of K is highest at 79%; 0.2 mm K > 0.08 mm K. During the coarse grinding stage, the medium exhibits a stronger crushing effect on coarse material particles.

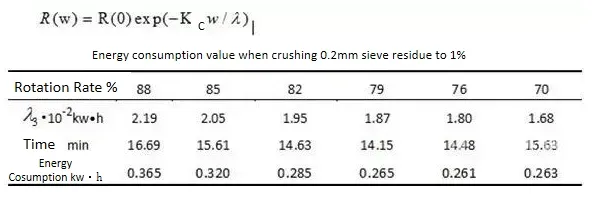

2.2.1.2 Relationship Between Rotation Speed and Grinding Energy Consumption

At a filling rate of 30%, grinding energy consumption increases as the rotation speed rises from 70% to 88%. The energy consumption is relatively low between 70% and 79%, reaching its minimum at 76%. When the rotation speed is too low, grinding time is prolonged. The optimal rotation speed falls between 76% and 79%.

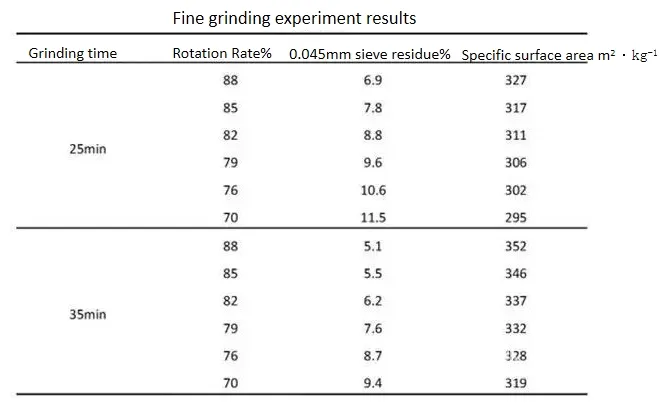

2.2.2 Fine Grinding Experiment

2.2.2.1 Relationship Between Rotation Rate, Grinding Speed Constant, and Grinding Energy Consumption

At a filling rate of 30%, as the rotation rate increases from 70% to 88%, the grinding speed constant rises and grinding energy consumption decreases. Therefore, the overall grinding effect improves at higher rotation speeds.

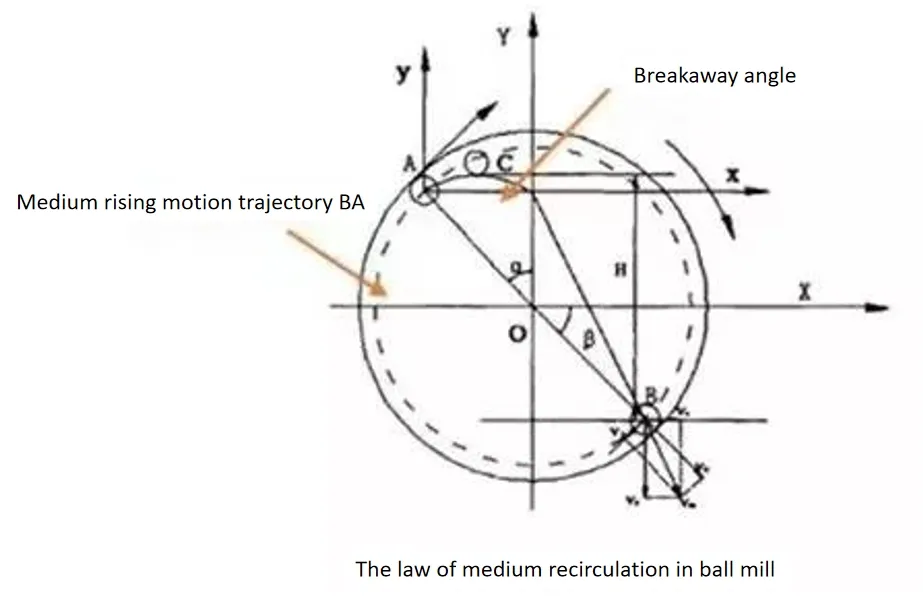

3. The Movement of the Medium at Different Rotation Speeds and Filling Rates

As the rotation speed increases, the amount of medium performing a falling motion also increases (as shown in the figures below).

3.1 The Influence Mechanism of Filling Rate on Grinding Effect

When the filling rate is 18%, the grinding effect is better than when it is 30%. Due to the influence of relative sliding, the curve for the 18% filling rate shifts to the left as a whole.

Overall, the grinding effect at a 18% filling rate is superior to that at a 30% filling rate.

III. Conclusion

The following conclusions can be drawn from the experiments:

1. When the filling rate is 18%, as the rotation rate increases from 58% to 88%, energy consumption for achieving the same fineness decreases, and energy consumption for achieving the same specific surface area also decreases. The difference in energy consumption between different rotation rates becomes more pronounced as the target fineness decreases and the target specific surface area increases.

2. When the filling rate is 30%, as the rotation rate increases from 70% to 88%, the crushing speed constant initially increases and then decreases, showing a parabolic trend. Meanwhile, crushing energy consumption increases. At a filling rate of 76%-79%, the crushing speed constant is higher, and crushing energy consumption is lower. The grinding speed constant increases and grinding energy consumption decreases. The optimal rotation speed for the best grinding effect is higher than that for the best crushing effect.

3. Normal impact energy is the primary factor affecting the crushing effect. When the rotation speed is below 79%-82%, normal impact energy is the main factor influencing the grinding effect. Above this range, tangential grinding energy becomes the primary factor affecting the grinding effect.

4. As the filling rate increases, the distance the ball mill medium falls decreases, and the energy it carries also diminishes. The kidney-shaped peristaltic zone at high filling rates is larger than at low filling rates. At the same speed, the crushing and grinding effects are better at a low filling rate compared to a high filling rate.

IV. Industrial Experimental Results and Conclusions

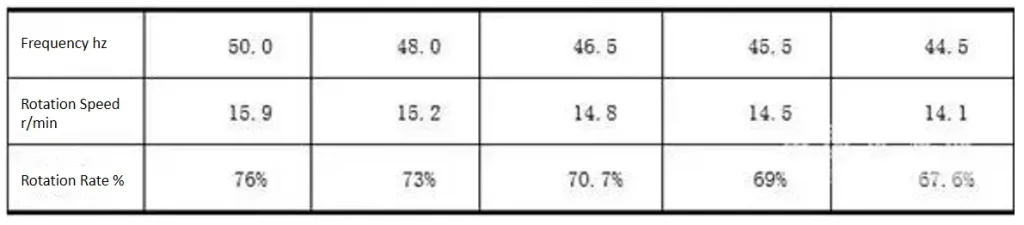

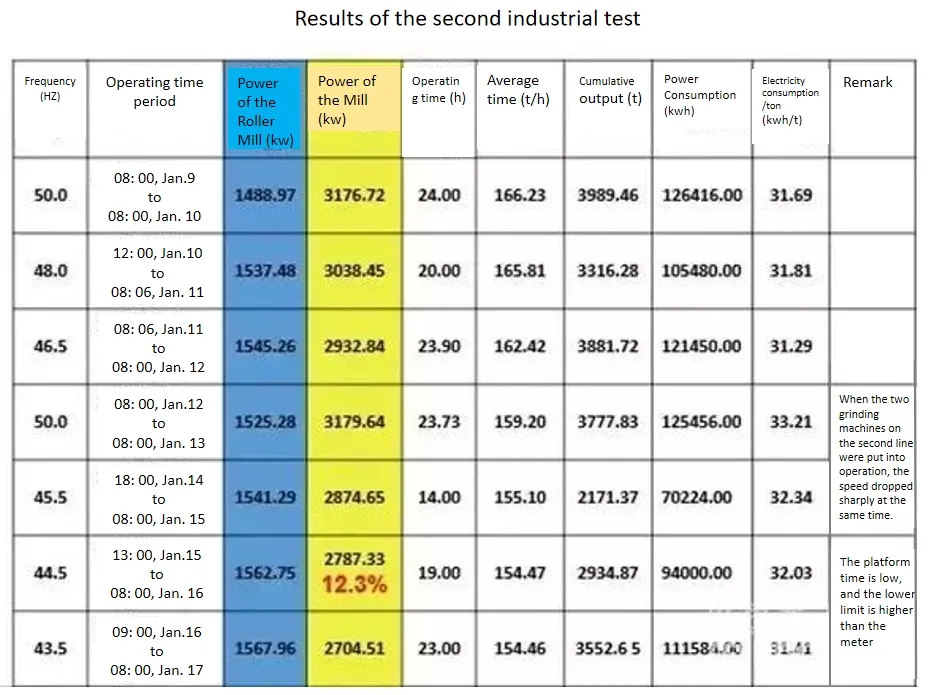

The experiment was conducted using frequency conversion speed regulation on a large mill at a company in Guangdong. The setup was a roller press semi-final grinding system combined with an open circuit ball mill. Due to significant vibration issues with large-scale grinding equipment, only this machine was used for speed reduction. A total of three experiments were carried out.

The configuration of the company’s #5 cement grinding system is as follows: a Φ1.7×1.1m roller press (with a configured power of 1800 kW) + V1000 type powder selector semi-final grinding system + an open circuit ball mill (with a configured power of 3550 kW). The effective inner diameter of the ball mill is 4.08 m, the effective length of the head bin is 3.5 m, and the effective length of the tail bin is 8.6 m.

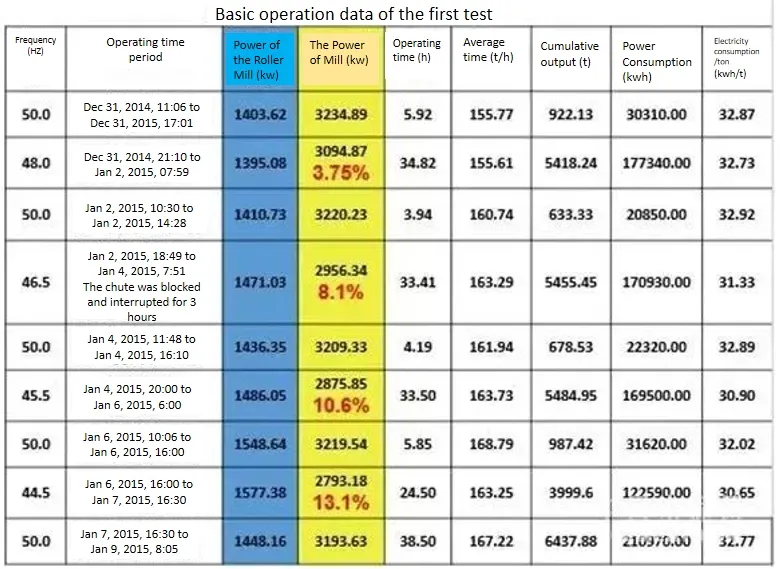

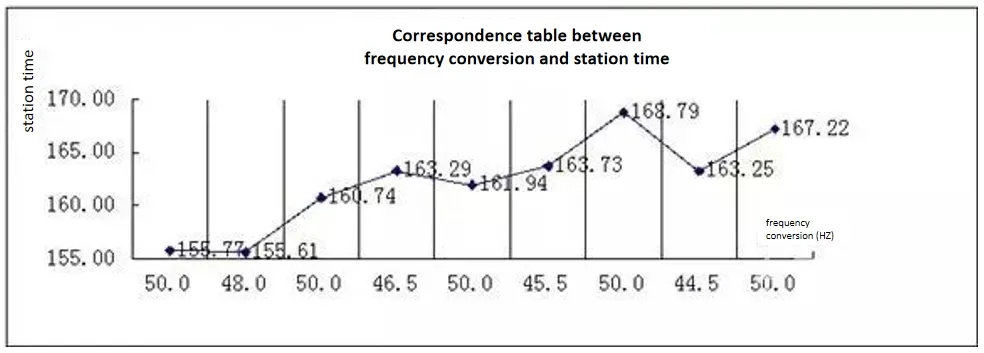

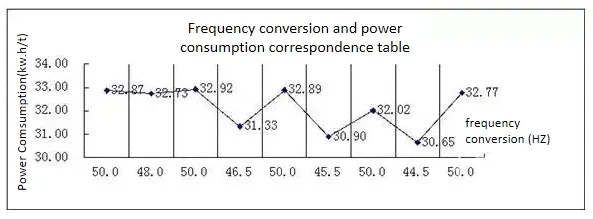

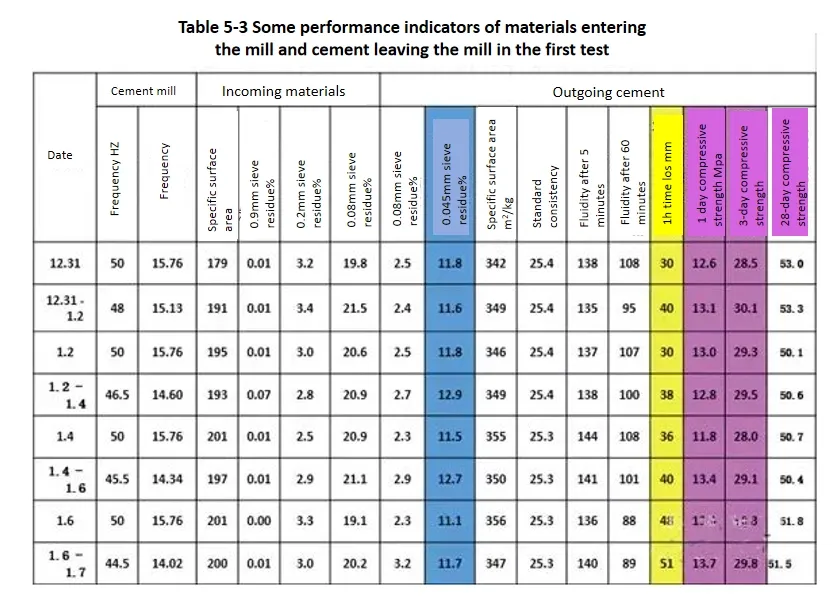

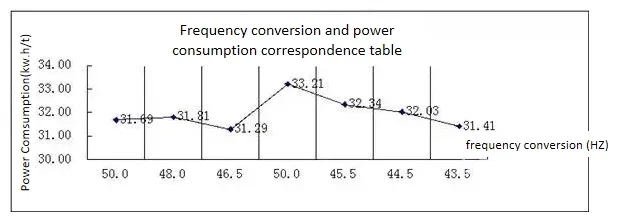

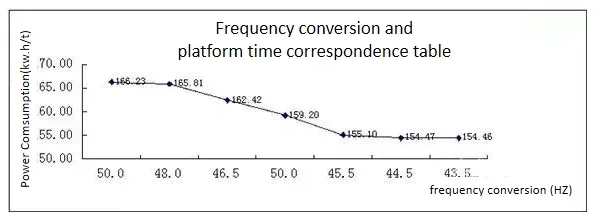

The first industrial test data (as shown below):

Summary of Industrial Trials for the Combined Grinding System of Roller Press Semi-Finish Grinding + Open- Circuit Ball Mill

1. In the existing roller press semi-final grinding + open-circuit ball mill combined grinding system, implementing frequency conversion and speed reduction on the cement mill significantly reduces its operating power. This adjustment increases the operating power ratio of the roller press to the ball mill and achieves notable power savings. The cement mill speed was modulated from 50 Hz to 44.5 Hz, resulting in a 12% reduction in ball mill operating power, a 3.5%-6.2% decrease in power consumption per ton of cement, and a reduction of 1-1.5 kWh per ton of cement. Although unit output slightly decreased, the product particle distribution showed a tendency to widen, early strength increased slightly, and physical properties remained largely unchanged, meeting the enterprise’s quality control requirements.

2. Guiding Significance for Industrial Cement Grinding System: The optimal speed for the best grinding effect is higher than that for the best crushing effect. The industrial mill is set to a speed rate of 76% for the best crushing effect. Consider using frequency conversion technology to increase the ball mill speed, reduce the ball mill filling rate, or replace the grinding media with lower-density options. This approach can improve overall grinding energy utilization and enhance the power saving effect. Further research on combining ceramic balls as grinding media with cement mill frequency conversion may also be beneficial.

If you have more questions about ball milling, please contact Epic technical team for more information.