NEWS

Replacing graphite anode with chlorine doped lithium titanate in the United States for high-capacity lithium batteries

Lithium titanate nanoflowers (Brookhaven National Laboratory)

The working principle of lithium batteries is that during charging, lithium ions move between the positive electrode (cathode) and the negative electrode (anode); During discharge, lithium ions move in the opposite direction. Nowadays, lithium batteries used in smartphones, laptops, and electric vehicles typically use graphite anodes. During charging, lithium ions will be inserted into the graphite anode; When using the battery, lithium ions will be removed from the battery.

Although graphite can withstand hundreds or even thousands of charge and discharge cycles, it cannot store enough capacity for energy intensive applications. For example, the range of electric vehicles is not long enough. In addition, graphite cannot charge and discharge at a high rate (power). Therefore, scientists have been searching for alternative anode materials.

Lithium titanate (LTO) is a promising anode material composed of lithium, titanium, and oxygen. In addition to being able to charge and discharge at high rates, LTO also has good cycling stability and sufficient space to accommodate lithium ions (with a large capacity). However, the poor conductivity of LTO can lead to a slow diffusion rate of lithium ions in the material.

According to foreign media reports, Amy Marschilok, a part-time faculty member and associate professor of chemistry at Stony Brook University’s Department of Materials Science and Chemical Engineering, stated that the available capacity of pure LTO is moderate, but it cannot quickly transmit electricity. Amy Marschilok also serves as the Deputy Director of Center for Mesoscale Transport Properties, as well as the Energy Storage Division Manager and Scientist at the Brookhaven National Laboratory, an interdisciplinary department of the US Department of Energy. She also stated that high-speed battery materials are very attractive for applications such as electric vehicles, portable power tools, and emergency power systems that require rapid energy storage within a few minutes.

Marschilok is also a member of the Brookhaven National Laboratory Stony Creek team, which has been collaborating on LTO research since 2014. In recent research, the team added chlorine to LTO through a doping process, thereby increasing its capacity by 12%.

Stanislaus Wong, an outstanding professor in the Department of Chemistry at Shixi University and an important researcher in the student research team, stated that controlled doping processes can alter the electronic and structural properties of materials. In my team, we are interested in using chemical knowledge to guide the design of favorable structure property correlations. Regarding LTO, adding doped atoms can improve its conductivity, expand its lattice, and widen the lithium ion transport channel. Scientists have tested many different types of dopants, but have not studied chlorine much.

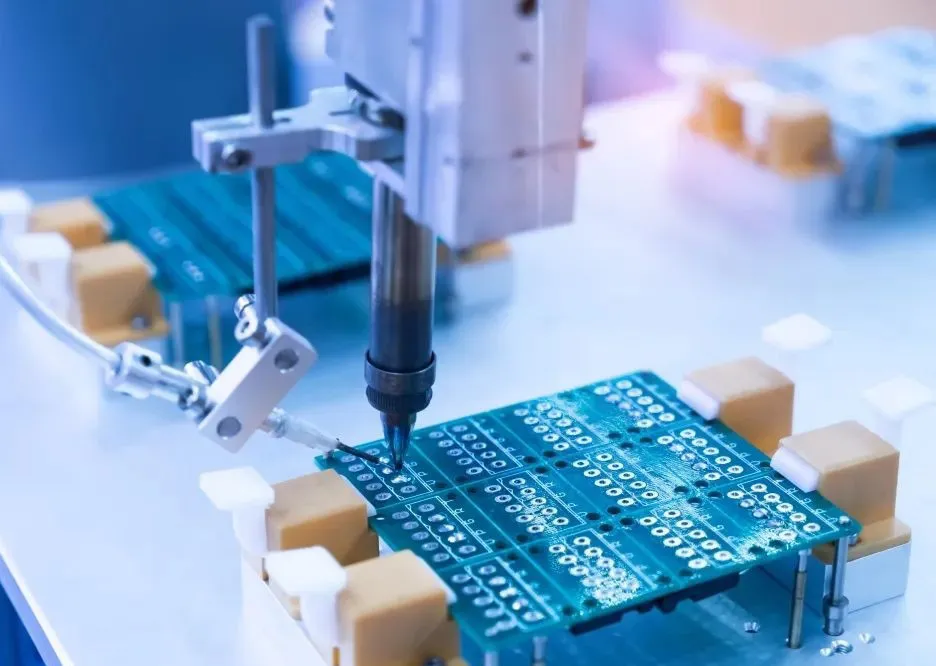

In order to manufacture LTO doped with chlorine, the team used a solution method called hydrothermal synthesis. During the hydrothermal synthesis process, scientists added a solution containing the relevant precursor (the reaction material used to produce the desired product) to the water, placed the mixture in a sealed container, and left it at a relatively moderate temperature and pressure for a period of time. In this case, in order to expand the experimental scale, scientists chose liquid titanium precursors instead of the solid titanium foil used in previous reactions. After hydrothermal synthesis of pure LTO and chlorine doped LTO for 36 hours, scientists employed additional chemical treatment steps to separate the required materials. The team also conducted imaging studies using scanning electron microscopy (SEM) in the electron microscopy facility of the Functional Nanomaterials Center (CFN) at the Brookhaven National Laboratory, and found that both samples had flower shaped nanostructures, indicating that the chemical treatment process did not damage the original structure of the materials.

Wong stated that our new synthesis method promotes fast, uniform, and efficient reactions, enabling the large-scale production of such 3D nanoflowers. This unique architecture has a large surface area, with petals radiating outward from the center, providing multiple pathways for lithium ions to enter the material.

By changing the concentrations of chlorine, lithium, and precursors, the purity of precursors, and the reaction time, scientists have found the optimal conditions for creating high crystal nanomaterials. Scientists conducted several electrochemical tests using optimized samples and found that when the battery was discharged at a high rate for 30 minutes, chlorine doped LTO had a large available capacity, and this performance was still maintained after more than 100 charge and discharge cycles.

To understand why performance can be improved, the team used computational theory to model the structural and electronic changes caused by doping chlorine. When calculating the most stable geometric structure of LTO doped with chlorine, the team found that chlorine prefers to replace the position of oxygen in the LTO structure.

Next, the team will investigate how the shape of 3D nanoflowers affects lithium ion transport. In addition, they are also exploring alternative materials for atomic level anodes and cathodes to improve lithium ion transport.