1. Quais benefícios os processos de modificação podem trazer aos fabricantes de carbonato de cálcio moído (GCC)?

Em primeiro lugar, a modificação do revestimento superficial com carbonato de cálcio melhora o desempenho do pó de GCC. Quando modificadas com ácido esteárico, as partículas de GCC têm menor probabilidade de se aglomerar, garantindo melhor dispersão na matriz. Além disso, o processo de modificação reduz as lacunas entre as partículas, diminuindo significativamente o valor de absorção de óleo. Isso, por sua vez, diminui a quantidade necessária de polímeros orgânicos ou resinas e reduz os custos.

Mais importante ainda, o processo de modificação aumenta significativamente o valor agregado dos produtos de GCC. O preço de mercado do pó de GCC comum varia de 200 a 600 CNY por tonelada, mas devido ao excesso de capacidade, a concorrência é acirrada. Em contraste, o pó de GCC revestido e modificado normalmente é vendido por 800 a 1.200 CNY por tonelada, com alguns pós modificados de alta qualidade chegando a 1.800 a 2.200 CNY por tonelada.

Portanto, o processo de modificação é uma ferramenta poderosa que ajuda os fabricantes de GCC a se libertarem do mercado extremamente competitivo do "oceano vermelho" e a explorarem as oportunidades mais lucrativas do "oceano azul".

2. Quais são os principais processos de modificação do carbonato de cálcio moído (GCC)?

1) Modificação do misturador de alta velocidade

Após décadas de desenvolvimento e iteração, a modificação do misturador de alta velocidade se tornou um dos processos de modificação mais maduros e estáveis.

O processo envolve primeiro a secagem do pó de GCC para reduzir seu teor de umidade abaixo de 1%. Simultaneamente, ácido esteárico é aquecido até a liquefação. As lâminas de rotação rápida do misturador de alta velocidade criam um fluxo turbulento, dispersando eficazmente o pó de GCC e garantindo uma mistura completa com ácido esteárico, completando o revestimento da superfície. Este método é simples de operar, requer equipamentos de baixo custo e produz pó de GCC modificado de alta qualidade e consistência.

Os processos de misturadores de alta velocidade mais avançados podem atingir uma taxa de modificação superior a 95%, com dosagem de ácido esteárico abaixo de 2%. Como o ácido esteárico custa aproximadamente 11.000 CNY por tonelada, reduzir sua dosagem em apenas 1% na produção em larga escala pode economizar milhares de yuans em custos diários. No entanto, a capacidade de modificação do misturador de alta velocidade é limitada, tornando-o adequado para modificações em pequenos lotes em laboratórios ou produção piloto.

2) Modificação do moinho de pinos

A modificação do moinho de pinos é atualmente o processo mais eficaz, alcançando uma taxa de modificação de até 99%.

Semelhante ao método do misturador de alta velocidade, o pó de GCC é seco e o ácido esteárico é aquecido até se liquefazer. Nesse processo, dois discos de pinos giram em alta velocidade em direções opostas, dispersando o pó de GCC e garantindo que o revestimento de ácido esteárico ocorra dentro da câmara.

Este método é altamente complexo, frequentemente exigindo semanas de ajustes de parâmetros. É mais adequado para modificações contínuas e em larga escala no GCC. A dosagem de ácido esteárico é inferior a 1%, reduzindo ainda mais o custo unitário da modificação. No entanto, os moinhos de pinos são caros, exigem pessoal qualificado para operação e manutenção, e são adequados apenas para empresas de grande porte com fortes capacidades técnicas.

3) Máquina de modificação de três rotores

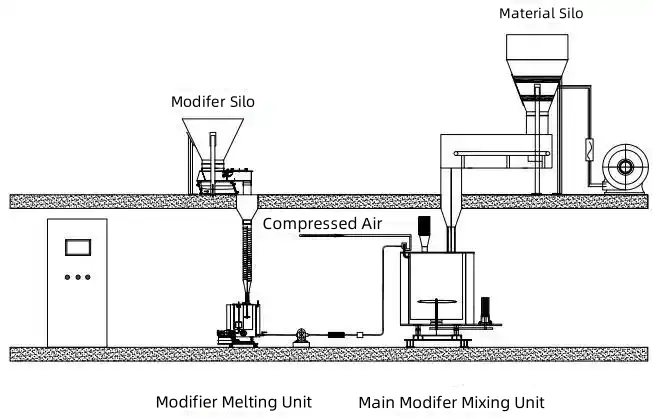

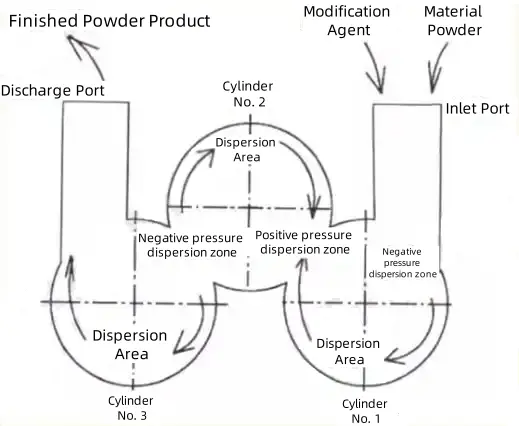

O processo de modificação de três rotores é amplamente utilizado na China. A máquina consiste em três rotores dispostos em uma estrutura em forma de "品", formando a câmara de ativação. Ela opera em modo contínuo e pode ser usada de forma independente ou conectada a equipamentos de moagem.

O processo utiliza três rotores girando em alta velocidade, gerando temperaturas de câmara de 120 a 140 °C. Isso cria turbulência dentro da câmara, garantindo a dispersão eficaz e o revestimento do pó de GCC com ácido esteárico. Todo o processo de modificação ocorre dentro da câmara.

A taxa de modificação para este processo excede 95%, com uma dosagem de ácido esteárico de cerca de 4%. O custo de uma máquina de modificação de três rotores é menor do que um moinho de pinos, mas maior do que um misturador de alta velocidade. Embora exija manutenção profissional, sua complexidade é menor do que a de moinhos de pinos, tornando-a uma escolha popular para fabricantes de médio porte.

3. Como avaliar os resultados da modificação?

Um método geral e intuitivo para avaliar a modificação do pó de GCC é o seguinte:

1) Princípio

Este método avalia o grau de revestimento da superfície com base nas características hidrofóbicas do carbonato de cálcio modificado.

2) Equipamento de teste

Proveta graduada de 100 mL com rolha

3) Etapas de análise

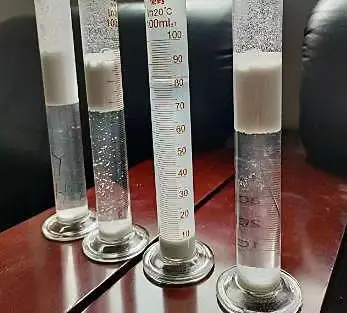

- Despeje 20 mL de água destilada no cilindro graduado de 100 mL.

- Pese com precisão 5 g (±0,01 g) da amostra e coloque-a no cilindro.

- Adicione água até atingir a marca de 80 mL, feche o cilindro e agite-o para cima e para baixo por 30 segundos (240 agitações por minuto).

- Deixe a mistura descansar por 30 minutos e registre os dados.

4) Imagens do Processo de Teste

Após a sedimentação, o grau de ativação pode ser avaliado visualmente por meio de imagens da amostra.