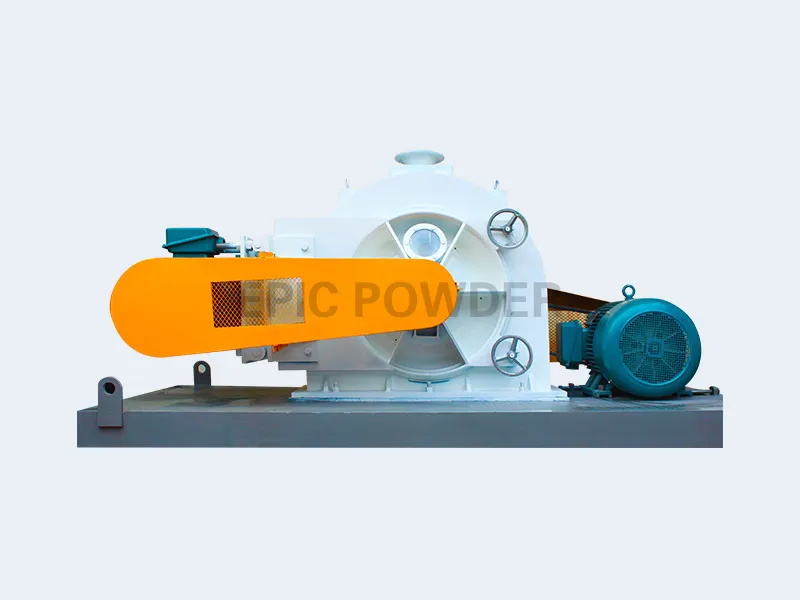

Pin mill for calcium carbonate coating

This system is most commonly used for coating calcium carbonate with stearic acid to meet the requirements for fillers used in the plastics industry.

The EPIC’s proprietary injector design achieves a high degree of atomization of the coating fluid, while the high tip speeds produced by the counter-rotating pin disks provide the high shear forces required for proper dispersion and uniform coating. Each coating system is custom designed for the application and includes all auxiliary equipment. Because of its unmatched efficiency, the Pin mill for the Calcium carbonate coating system consumes less power and fluid than any other method in use today.

- This machine provides continuous coating process.

- This type of machine is very popular in European and American markets.

- Two motors run in opposite direction. The linear speed can be up to 240m/s.

- High speed impact, shear and friction leads to full dispersion of materials and due to it, temperature of the material rises resulting in powder modification completely.

According to different materials and application industries, the production capacity and particle size range will be different.

Please contact our engineers to customize the equipment for you. Our experts will contact you within 6 hours to discuss your needs for machine and processes.

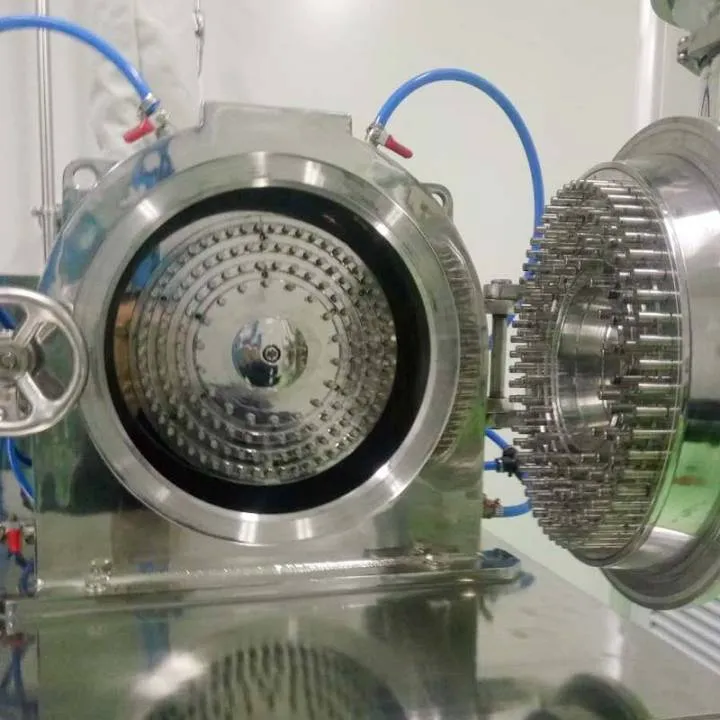

What is the working principle of Pin Mill Coating Machine?

The pin mill is a fine impact mill with two driven pin discs. In counter-rotating mode, much higher relative speeds are possible than with the ACM fine impact mill with only one driven pin disc. The highest relative speed develops at the outermost pin rows and can be up to 240 m/s.

The fineness can be adjusted by altering the pin disc speeds. The centrifugal forces acting on both discs ensure that even moist, greasy and sticky products can be processed. The design with the wide-chamber housing is ideal for processing these kinds of products. The feed material is often embrittled by intensive mixing with liquid nitrogen.

The mill door can be hinged opened wide to permit easy cleaning.

Where can I go to learn more and see examples of other businesses buying Pin Mill Coating Machine?

Provide you with relevant cases of Pin Mill Coating Machine, show the introduction of each case information, application products, and customer evaluation information.

Production Line of Lithium Iron Phosphate for an Electric Vehicle Company in Huizhou

The company is a Chinese car manufacturer and one of the world’s second-largest producers of rechargeable batteries. As one of the earliest Chinese enterprises engaged in the manufacture of new energy materials, it possesses strong technical capabilities and significant influence in the industry. The company has maintained a successful partnership with Epic Powder. During its

A New Material Company in Zhejiang: Metal powder grinding equipment

The customer is a large domestic enterprise. To expand production capacity and improve efficiency, they needed grinding equipment with reliable performance, stable operation, and high yield. After investigation, they found that the grinding mills provided by Epic were more in line with the enterprise’s expected research outcomes. They also reviewed Epic’s experience and reputation

Silica soil drying and dispersing modification production line of a mineral products company in Jiangsu

This mineral company has the mining right. Also the mineral products have special physical and chemical indexes, which is difficult to process. The whole process flow is complicated and has high processing cost. Recommended by peers, it purchased two sets of drying and shattering-modified mechanical pulverizer production lines, and now the company has become a

Air Classifying production line of carbon microspheres in a chemical plant in Hubei

In recent years, the new energy industry has developed rapidly. This customer seized the opportunity to expand carbon microspheres production. Epic’s abundant cases in the new energy industry attracted the customer. Before purchasing the equipment, this customer visited Epic Powder‘s factory for two inspections and then finished material tests. The results were quite satisfactory. Epic

A ball milling and modification production line in a calcium carbonate factory in Iran

This customer, a prominent non-metallic ore processing enterprise in Iran, sought a new coating modification process. After exploring various options, he discovered Epic’s extensive experience in ultrafine processing and advanced modification of non-metallic ores. After two successful tests, he decided to purchase two sets of ball-milling classification and modification equipment to process calcium carbonate. Raw

Milk powder grinding production line of a company in Menggu

This customer is a well-known milk enterprise in China. During the launch of their freeze-dried milk powder project, they faced issues such as material sticking after heating and weight inconsistencies. Through local pharmaceutical companies, they discovered Epic‘s ultra-micro grinding technology for health products. After thorough investigation, experimentation, and structural optimization, Epic successfully resolved

How do I choose the right model for my needs?

EPIC Powder Machinery offers one different types of Pin Mill Coating Machines to choose from. See the table below to compare their basic specifications and system requirements.

| Type | Model | 200 | 400 | 500 | 630 | 800 |

|---|---|---|---|---|---|---|

| Coarse powder | Fineness(mesh) | 20 - 200 | 20 - 200 | 20 - 200 | 20 - 200 | 20 - 200 |

| Speed(m/s) | 75 - 85 | 75 - 85 | 75 - 85 | 75 - 85 | 75 - 85 | |

| Power(kw) | 7.5 | 18.5 | 22 | 37 | 55 | |

| Fine powder | Fineness(mesh) | 60 - 300 | 60 - 300 | 60 - 300 | 60 - 300 | 60 - 300 |

| speed(m/s) | 100 - 120 | 100 - 120 | 100 - 120 | 100 - 120 | 100 - 120 | |

| Power(kw) | 11 | 30 | 37 | 55 | 75 | |

| Ultra fine powder | Fineness(mesh) | 100-2500 | 100-2500 | 100-2500 | 100-2500 | 100-2500 |

| Speed(m/s) | 200-240 | 200-240 | -- | 200-240 | 200-240 | |

| Power(kw) | 11 x 2 | 30 x 2 | -- | 55 x 2 | 90 x 2 |

Show details of our Pin Mill Coating Machines

Show the machine details related to the Pin Mill, the details determine the quality.

Related Products

GET IN TOUCH

Our experts will contact you within 6 hours to discuss your needs for machine and processes.

Factory Address:

NO. 369, Road S209, Huanxiu , Qingdao City, China