Calcium carbonate stands at the forefront of the industrial chain and is often referred to as “industrial food.” It’s an essential non-metallic mineral and a fundamental raw material in daily industrial production. It plays a vital role in both the national economy and daily life. This serves as a critical material for emerging industries and high-tech development. Below is a concise summary of calcium carbonate’s classification, applications, industrial chain, development status, and trends for your reference.

I. Classification and Applications

Calcium carbonate is primarily categorized into industrial calcium carbonate, edible calcium carbonate, and medicinal calcium carbonate. Industrial calcium carbonate is further subdivided into heavy calcium carbonate, active calcium carbonate, light calcium carbonate , and nano calcium carbonate.

This versatile material is widely utilized in various fields, including papermaking, plastics, coatings, rubber, inks, chemical building materials, adhesives and sealants, feed, personal care products, food, and pharmaceuticals. It also serves as a dietary supplement and antacid. Calcium carbonate is currently the most extensively used and largest inorganic non-metallic mineral powder.

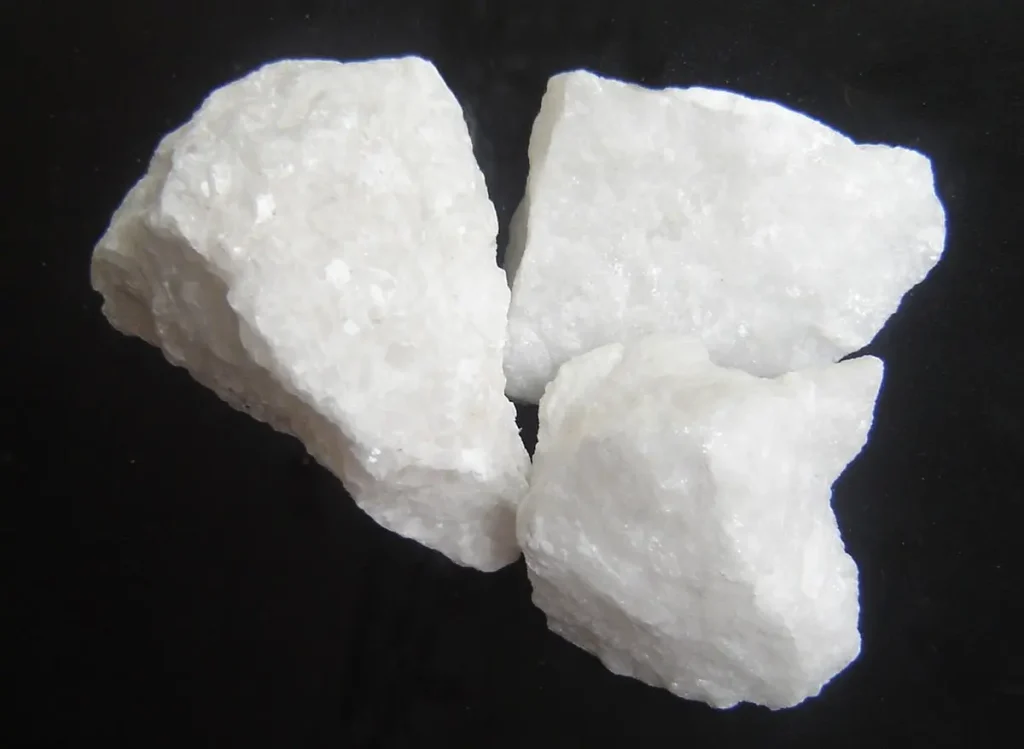

Heavy calcium carbonate: Produced by mechanically crushing natural calcite, limestone, chalk, shells, and other materials.

Light calcium carbonate: Also known as precipitated calcium carbonate (PCC). It is manufactured by calcining limestone and other raw materials to produce lime. Water is then added to the lime to form lime milk. It is carbonized by introducing carbon dioxide to produce calcium carbonate precipitate. The precipitate is subsequently dehydrated, dried, and crushed to obtain light calcium carbonate.

Active calcium: The production process is roughly the same as that of light calcium. However, the conditions are strictly controlled in the carbonization process. Such as improving the reaction tower, controlling the temperature and gas flow, and adding an activator to treat the surface of the calcium carbonate particles to produce active calcium carbonate with higher added value.

Nano calcium: It is a new type of ultrafine solid powder material. The abbreviation of nano calcium carbonate, with a particle size between 0.01-0.1μm.

III. Development Status and Trends

China possesses abundant, high-quality resources such as limestone and calcite, along with a vast consumer market. In recent years, the country has maintained its position as the world’s largest producer and consumer of calcium carbonate. The production and consumption of light calcium carbonate account for over 50% of the global total, while the output of heavy calcium carbonate contributes to more than 25% of the world’s total.

Around calcium carbonate resource mineral deposits, China has gradually established several calcium carbonate industrial bases. They’re Hezhou in Guangxi, Yongfeng in Jiangxi, Jiande in Zhejiang, Nanzhao in Henan, Lianzhou in Guangdong, Quzhou in Zhejiang, Chizhou in Anhui, Jingxing in Hebei, Linwu in Hunan, and Ya’an in Sichuan. However, due to limitations in resources, technology, funding, land availability, and cost control, local calcium carbonate enterprises generally lag behind leading foreign companies such as Omya, Imerys Ceramics, and Huber. Chinese enterprises are often small in scale, technologically outdated, industrially underdeveloped, lacking in independent innovation, and less competitive. They primarily produce low- to mid-end products, and China is not yet considered a global leader in calcium carbonate production.

As China’s economy transitions towards high-quality and sustainable development, the demand for high-end calcium carbonate products in industries such as plastics, rubber, coatings, and papermaking is expected to grow significantly. The calcium carbonate industry holds substantial development potential. It is evolving from the production of low-end, primary-processed products to high-end products such as nano calcium carbonate, ultrafine calcium carbonate, and medical-grade and food-grade calcium carbonate. At the same time, the industry is shifting toward functional and specialized calcium carbonate products, which represent the future direction of development.

IV. Development Strategies for the Calcium Carbonate Industry

In line with the development strategies of “reducing mining rights, extending the industrial chain, and increasing added value,” calcium carbonate industrial bases in regions such as Zhejiang, Henan, and Guangdong are poised to introduce a number of high-end calcium-based new material enterprises. Relying on local enterprises such as Omya and Guangyuan New Materials, these efforts aim to capitalize on high-quality mineral resources in areas like Qingyang County.

The industry will focus on promoting the deep processing of calcium-based raw materials and transitioning from low-end mining and rough processing to high-end calcium-based new materials. Such as nano calcium, active calcium, food-grade, and pharmaceutical-grade products. Efforts will also emphasize the development of downstream industries, including high-end coatings, sealants, plastic products, friction materials, food, and pharmaceuticals. By attracting high-quality enterprises and fostering innovation, the goal is to build a comprehensive industrial chain for high-end calcium-based new materials. So it can continuously advance the industry towards green deep processing and terminal applications.