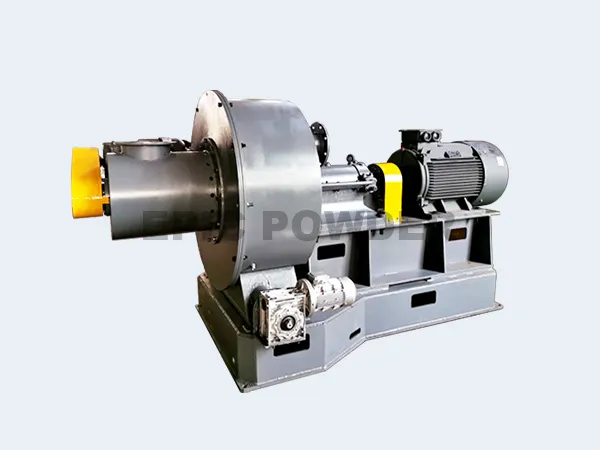

Impact Mill

The material is evenly fed into the grinding chamber by the feeding system, and is strongly impacted by the high-speed rotating crushing disc, and at the same time, it is subjected to various forces such as friction, shearing, and collision between the static disk and the ring gear, and is finally crushed.

Working Principle

The material is evenly fed into the grinding chamber by the feeding system, and is strongly impacted by the high-speed rotating crushing disc, and at the same time, it is subjected to various forces such as friction, shearing, and collision between the static disk and the ring gear, and is finally crushed. The crushing movable disk and static disk can be combined in different structures to meet the crushing requirements of different materials. The structural forms we currently design include: hammer type, pin type, turbine type, and grinding disc type.

Features And Benefits

- Hammer type is suitable for pre-crushing and coarse crushing.

- The pin type is suitable for brittle, viscous and heat-sensitive materials.

- Turbine type is suitable for brittle materials and fibrous materials.

- The grinding disc type is suitable for tough and elastic materials,such as plastics.

- Hammer type and turbine type generally have a built-in screen to control the fineness of the product.

- Explosion-proof design can meet the crushing requirements of flammable, explosive and oxidizable materials.

- Low temperature design can meet the crushing requirements of heat sensitive materials.

Related Products

Technical Parameters

Technical parameters of Impact Mill

| Type | Model | 160 | 250 | 360 | 500 | 630 | 800 |

|---|---|---|---|---|---|---|---|

| Blast mill MJL-B | Speed (r/min) | 12000 | 7500 | 5550 | 3850 | 3200 | 2800 |

| Power(kW) | 4 | 5.5-7.5 | *11-15 | 18.5-30 | 30-45 | 37-75 | |

| Fineness(mesh) | 20-325 | ||||||

| Hammer mill MJL-H | Speed (r/min) | 9000 | 6000 | 4680 | 2480 | 2300 | 2150 |

| Power(kW) | 4 | 7.5 | 22 | 37 | 22-45 | 55 | |

| Fineness(mesh) | 20-325 | ||||||

| Disc mill MJL-D | Speed (r/min) | 12000 | 7500 | 5550 | 3850 | 3200 | 2800 |

| Power(kW) | -- | -- | 15 | 30 | 45 | 8 | |

| Fineness(mesh) | 20-325 | ||||||

Project Cases

Production Line of Lithium Iron Phosphate for an Electric Vehicle Company in Huizhou

A New Material Company in Zhejiang: Metal powder grinding equipment

Silica soil drying and dispersing modification production line of a mineral products company in Jiangsu

Air Classifying production line of carbon microspheres in a chemical plant in Hubei

A ball milling and modification production line in a calcium carbonate factory in Iran

Milk powder grinding production line of a company in Menggu

GET IN TOUCH

Our experts will contact you within 6 hours to discuss your needs for machine and processes.

Factory Address:

NO. 369, Road S209, Huanxiu , Qingdao City, China