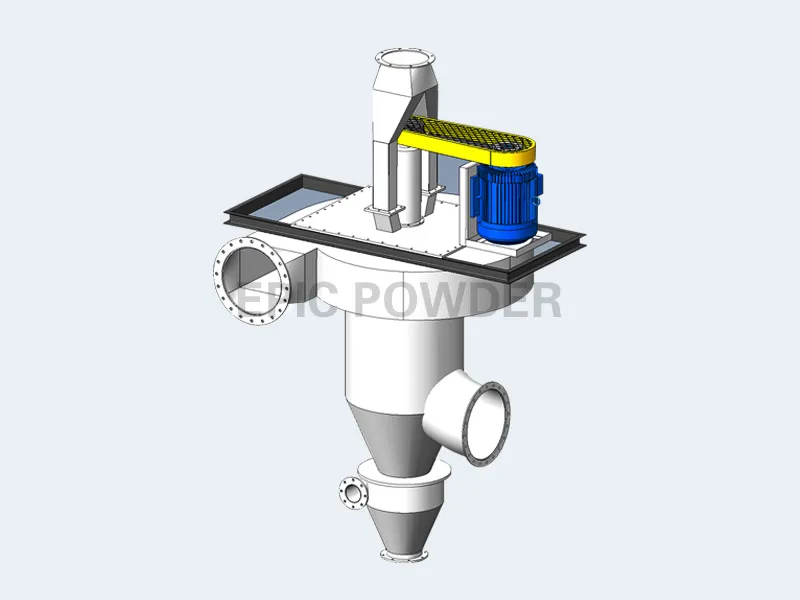

Air Separator

MBS series air classifier is jointly designed by our German experts and British experts, and is specially used for efficient dry classification of D97: 8-200 micron powder.

The classifier, cyclone collector, dust collector and induced draft fan form a complete classification system.

Working Principle

The feeding port of the classifier is at the top of the classifier. The feed enters the classifier from the top inlet under the action of gravity, and then falls onto the centrifugal dispersion disc of the classifying wheel. The material will be evenly dispersed, dispersed to the baffle ring and down into the grading area. Classification air enters the scroll housing, passes the guide vanes, and inwards to the classification wheel. The fine powder is carried by the airflow into the classifying wheel, and then enters the cyclone collector or dust collector with the airflow, while the coarse powder will be repelled by the centrifugal force of the classifying wheel and fall into the lower body of the classifier.

Features And Benefits

- The hierarchical structure design is unique, low pressure, low energy consumption.

- It is very good for apex cutting of ultra-fine products and medium-fine products.

- Applicable to a wide range of particle sizes, the coarsest can reach 200 microns.

- There are different models to meet different output, and the feeding capacity of the largest model can reach 800t/h.

- Wear-resistant design, can handle powder products with extremely high hardness.

- The design of internal air circulation can reduce investment and save floor space.

- It can be combined with a ball mill to form a closed-circuit production system for grinding various materials.

Related Products

Technical Parameters

Technical parameters of MBS series Air Classifier

| MODEL | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 | 17 | 18 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Drive power (kW) | 5.5 | 11 | 15 | 22 | 37 | 45 | 75 | 110 | 132 | 160 | 185 | 220 | 280 | 320 | 380 | 475 | 540 | 630 |

| Air flow rate(m³/h) | 2,800 | 4,700 | 8,600 | 15,200 | 23,400 | 31,000 | 49,000 | 74,000 | 107,000 | 150000 | 190,000 | 237,000 | 288,000 | 344,000 | 402,000 | 469,000 | 536,000 | 606,000 |

| Fineness D97 (μm) | 8 | 9 | 10 | 13 | 14 | 16 | 18 | 20 | 25 | 27 | 28 | 29 | 31 | 33 | 34 | 35 | 37 | 38 |

| Max. feed (t/h) | 4 | 6.6 | 12.1 | 21.3 | 32.8 | 43 | 68 | 100 | 140 | 210 | 260 | 330 | 400 | 480 | 560 | 650 | 750 | 840 |

Project Cases

Production Line of Lithium Iron Phosphate for an Electric Vehicle Company in Huizhou

A New Material Company in Zhejiang: Metal powder grinding equipment

Silica soil drying and dispersing modification production line of a mineral products company in Jiangsu

Air Classifying production line of carbon microspheres in a chemical plant in Hubei

A ball milling and modification production line in a calcium carbonate factory in Iran

Milk powder grinding production line of a company in Menggu

Latest News

GET IN TOUCH

Our experts will contact you within 6 hours to discuss your needs for machine and processes.

Factory Address:

NO. 369, Road S209, Huanxiu , Qingdao City, China