3. The beneficial effects of this equipment are:

1. When disposing of waste lithium batteries through high-temperature pyrolysis, the high-temperature waste gas generated during production is used to pyrolyze the batteries. There is no need to use natural gas as a heat source. Because it allows for the recycling of waste heat in the production process and addressing the issue of high-temperature support production equipment. The exhaust gas cooling device saves investment in the cooling system for production equipment.

2. In the tail gas treatment process, it’s another case. Since the cracked waste gas has already been burned at high temperature in the dry rotary furnace, the organic matter is completely and thoroughly decomposed. That eliminates the need for a tail gas combustion device.

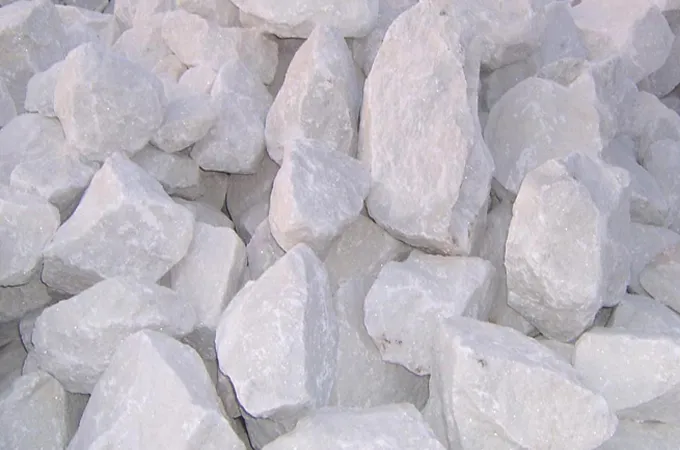

3. The waste gas containing fluorine and other halogens produced by pyrolysis is absorbed by calcium oxide. This removes the need for devices and measures to prevent the generation of dioxins and negates the need for an alkali spray system to absorb HF, significantly reducing investment and costs in environmental protection facilities and operational environmental management expenses. Therefore, using this equipment to process waste lithium batteries can reduce millions of yuan in investment in environmental protection facilities and lower energy consumption by 500 to 1,000 yuan per ton, yielding significant energy savings and cost reductions.

4. The recycling and reuse of waste lithium batteries

The recycling and reuse of waste lithium batteries have attracted wide public attention, especially concerning how to safely handle charged lithium batteries, which has become a critical issue. The materials processed by the charged crushing and air separation equipment for waste lithium-ion batteries include power-type, energy storage-type, and 3C-type single lithium-ion batteries and battery waste, covering cylindrical, soft-pack, and square batteries of common specifications, as well as defective battery products. The charged crushing device allows batteries to enter the crushing process directly without being discharged, greatly improving production efficiency and reducing operating costs. This equipment is equipped with real-time oxygen monitoring, temperature segmentation monitoring, video monitoring, and PLC-hosted centralized interlocking control to enhance process safety and ensure secure operation.

7 main advantages

1. The total power of the complete set of equipment is 300 kilowatts, and natural gas consumption for live crushing is less than 10m³.

2. The complete set of equipment covers an area of approximately 200 square meters (4m x 50m).

3. The high-temperature heat treatment of crushed or liquid raw materials ranges from 750 to 900 degrees Celsius. The tail gas is processed through a quenching tower, bag dust removal, activated carbon absorption, and spraying, meeting emission standards.

4. After high-temperature treatment, the treatment rate for battery organic matter exceeds 98%, and the diaphragm glue treatment rate is over 95%.

5. The equipment features complete environmental protection systems, a reasonable design, and high-quality materials. As it is manufactured in China, the environmental protection systems, including those for noise, wastewater, and waste gas treatment, are of high standards and fully compliant.

6. During the assembly of the complete set of equipment, the factory has a high level of completion and reasonable design, which greatly reduces the time needed for on-site installation and commissioning. Equipment installation is typically completed within 15 days.

7. This high-temperature heat treatment converter is designed based on practical operational and production experience both domestically and internationally. It is at a leading level among similar products, independently manufactured. For it has advantages such as relatively low cost, safety and reliability, strong continuity, and low energy consumption.

8. The complete set of equipment ensures stable production with a low maintenance rate. It offers distinct advantages over competitors in the industry. The equipment has a high degree of integration, occudpies a small footprint, and has low energy consumption. The recovery rate of black powder in one treatment is not less than 98%.