Calcium carbonate grinding mills are machines. They grind calcium carbonate (CaCO3) into fine powder for various uses. Calcium carbonate (CaCO₃) is a versatile, widely used inorganic compound. It occurs naturally in limestone, marble, and chalk. It is a key part of the Earth’s crust. It forms from both geological and biological processes. Calcium carbonate is a white, odorless powder or crystal. It has low water solubility, so it is stable under normal conditions.

A key use of calcium carbonate is in construction. It is a key ingredient in cement and concrete. Its ability to improve building materials makes it vital for infrastructure. Also, calcium carbonate is a common filler in paints, plastics, and rubber. It improves their texture and performance while cutting production costs.

Calcium carbonate powder, from a production view, comes from grinding limestone, marble, and calcite. The calcium carbonate production line has several key parts. They are crushers, screw conveyors, storage bins, grinding mills, dust collectors, and classifiers. The grinding mill is the core of the entire production line.

The type of grinding mill affects the quality of the final calcium carbonate powder. So, many customers want to know how to choose the right grinding equipment. This article will provide you with some suggestions.

Production method of calcium carbonate powder

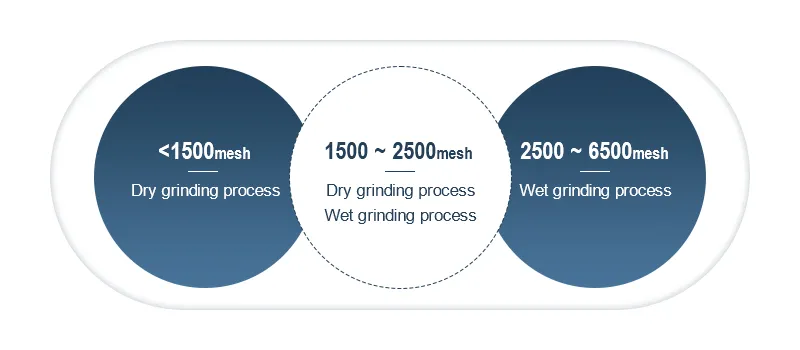

Before choosing a grinding mill, you must know how to produce calcium carbonate. There are currently two main methods: dry grinding and wet grinding.

Dry grinding is mainly for primary grinding. It is for making powders with a loose particle size distribution.

The wet method uses coarsely crushed products as raw materials. It adds solvents and additives for re-grinding. It removes impurities in the ore to improve the fineness and purity of the finished product.

Dry grinding usually produces finished products with particle sizes below 1500 mesh.

For products with particle sizes from 1500 to 2500 mesh, dry screening or wet screening can be used.

For products with particle sizes from 2500 to 6500 mesh, wet grinding is usually used.

| Grinding calcium carbonate | Advantages | Disadvantages |

| Dry grinding process | The cost of the equipment is low, and the industry is mature. It is easy to manage production, adjust the process, and make products with varying needs. The final products, with specific requirements, can be modified after production. | Generally, it is primary crushing and the finished product particles are larger. |

| Wet grinding process | Large-scale continuous production; The finished product can have a very fine particle size. This can meet some special production requirements. The slurry has a high solid content, low viscosity, and good dispersibility. It can meet various customers’ needs and produce high-quality, heavy calcium carbonate. | The equipment investment is large and the operating cost is high; The finished product is difficult to transport and is suitable for local use. |

Understanding Calcium Carbonate Grinding Mills

Calcium carbonate grinding mills are vital in many industries. These include construction, agriculture, and pharmaceuticals. These mills efficiently reduce calcium carbonate particles to meet various application needs. Calcium carbonate is a natural mineral. It comes mainly from limestone, marble, and chalk.

The grinding process involves several stages, including crushing, milling, and classifying. Initially, large chunks of calcium carbonate are crushed into smaller pieces using crushers. Next, the crushed material goes to grinding mills. There, it is further reduced in size. Several types of grinding mills are used for this. They include ball, roller, and air classifier mills. Each type has its benefits. They depend on the desired particle size, production capacity, and energy efficiency.

Types of Calcium Carbonate Grinding Mills

Ball mill

A ball mill is often paired with a classifier. This forms a complete production line. It mainly produces D97, 5 to 45μm ground calcium carbonate, both fine and ultrafine powders. The output of the ball mill varies with different models. Generally speaking, the annual output of a ball mill is between 10,000 tons and 200,000 tons.

Its advanced tech, high-quality products, and stability appeal to mid- and high-end customers.

Micro powder roller mill

The name says it all. The micro powder roller mill crushes materials by rolling multi-layer ring rollers. It is mainly used to produce ultra-fine powders of 8-45μm.

Our common micro powder roller mill models come in 21 rollers, 28 rollers, and 34 rollers. The more rollers there are the greater the output.

Raymond mill

Raymond mill is mainly used for coarse powder grinding. The feed particle size is 25-30mm. The discharge size is 45-180μm. The pass rate can reach 99%. Other grinders find this hard to match. It also has a small footprint, is easy to maintain, and consumes little energy.

It outputs 1 to 30 tons per hour. The output varies with the finished particle size. Raymond Mill is widely used and welcomed by users at home and abroad.

Vertical mill

A vertical mill is a large grinding machine. It is widely used in cement, electricity, metallurgy, and chemicals. It is often used to produce powder as fine as 10 microns. Vertical mill has large output and small footprint.

The vertical mill’s powder output is not as good as the ball mill’s. But, its power consumption is 30% to 50% lower. So, for customers who want low power use, a vertical mill is best.

Factors to consider when selecting a calcium carbonate grinding mill

Raw materials

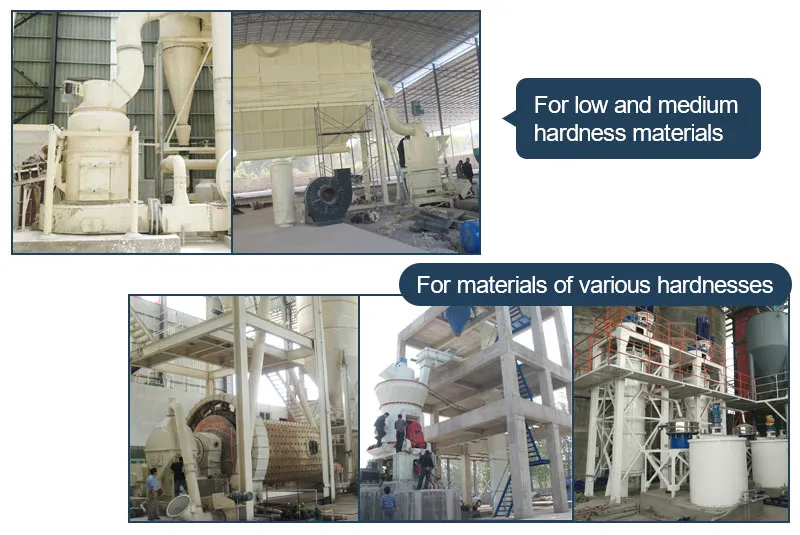

Different raw materials have different hardness. The hardness of the material suitable for different grinding mills is also different. We have several calcium carbonate grinding mills. They are a ball mill, micro powder roller mill, Raymond roller mill, vertical mill, and a wet grinding mill.

Raymond and micro powder roller mills suit medium to low hardness materials. Ball mills, vertical mills, and wet grinding mills suit a range of hardness in materials. Only by choosing the right grinding mill can its production efficiency be maximized.

Feeding and output size

Before choosing a grinding mill, know your material’s size and the desired product size. This will help you choose a suitable mill.

| Equipment | Feeding size | Output size |

| Ball mill | 0-4mm | 5-45μm |

| Micro powder roller mill | 0-10mm | 5-45μm |

| Raymond roller mill | 25-35mm | 45-180μm |

| Vertical mill | 0-40mm | 3-45μm |

| Wet grinding mill | About 45μm | 0-5μm |

Capacity

You need to estimate the amount of powder you need per day or year. Knowing this factor requires consideration of the machine’s configuration. If one machine can’t meet your production needs, use two or more mills.

Example: A wet grinding mill. Two parallel wet grinding mills can greatly boost output. In contrast, two series wet grinding mills can improve the finished product’s fineness.

The shape and quality of the finished product

For some non-metallic minerals, like graphite and talc, their flake or needle shape is important. It helps improve their performance and value. Some downstream industries prefer a spherical or nearly-spherical finished product.

So, the particle shape matters when choosing a mill for these minerals. Generally, the shape and quality of the finished ball mill will be better.

Energy consumption

Energy use is key when choosing a calcium carbonate mill. It affects equipment costs.

Of common grinding equipment, ball and wet mills use the most energy. Raymond, micro powder roller, and vertical mills use the least.

Applications

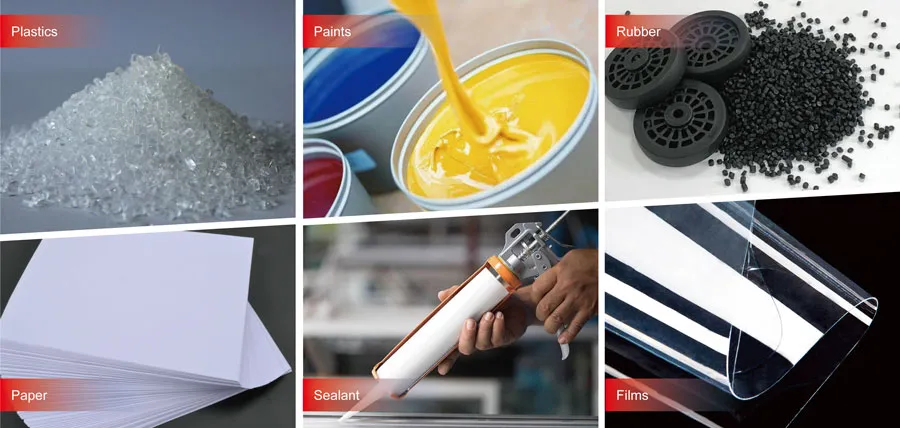

Different industries have different requirements for using ground calcium carbonate powder. Take the following industries as examples:

- The rubber industry requires 400 mesh. It uses it in filling materials to cut costs and improve strength and wear resistance.

- The plastic industry needs 400 mesh. It is used to improve stability and surface smoothness.

- The paint industry requires 800 mesh, and the main function is to ensure that the filling amount is more than 30%;

- The paper industry needs 325 mesh. It must ensure the paper’s strength and whiteness, and be low-cost.

- The construction industry needs 325 mesh. It increases the product’s toughness and strength.

Input costs

Customers worry about the high cost and slow ROI of new equipment. Based on the above, first choose the right equipment for your project. Then, compare the prices of different manufacturers.

If you need to grind fine powder on a tight budget, consider a micro powder roller mill. Similarly, if you need a fine powder, and have the budget for it, consider a ball mill for high quality.