Heavy calcium carbonate dry production process and equipment

Heavy calcium carbonate is made from natural minerals such as calcite, marble, limestone, chalk, etc., and is processed into powder products that meet the fineness requirements of the application field.

Among them, the dry process is generally used to produce heavy calcium carbonate products with d97≥3-5μm. The main crushing equipment includes Raymond mill, impact mill, dry stirred mill, air flow mill, vertical mill, roller mill, vibration mill and ball mill.

Heavy calcium carbonate dry process production equipment and product characteristics

Processing equipment | Product fineness | Application areas |

Large Raymond mill Vertical mill | 45μm | Low-end paper filling materials, shoe sole fillers, home decoration board materials, dry powder mortar, feed, power plant desulfurization, wet processing raw materials, etc. |

Raymond mill Ring roller mill Vertical mill | >15-45μm | Paper filling and coating materials, plastics and their profiles, rubber, non-woven fabrics, artificial marble slabs, wet grinding and deep processing raw materials, etc. |

Ring roller mill Vertical mill Ball mill | 10-15μm | Paper (surface) coating materials, non-woven fabrics, paints, coatings (water-based), mid-to-high-end plastic masterbatches, mid-to-high-end rubber masterbatches, etc. |

Ring roller mill Vertical mill secondary classification Ball mill + classification | <10μm | Papermaking coatings, high-end plastic masterbatches, paints and coatings and other industries with higher functional requirements |

1. Raymond mill

Raymond mill is widely used to produce heavy calcium carbonate products with a size of 38-74μm (200-400 mesh). After modification and configuration of fine classifier, it is also used to produce fine powder with a size of d97=30-15μm (500-800 mesh).

Raymond mill has the advantages of small footprint, high finished product screening rate, strong system and reliable operation, but it also has problems such as too low volume content of 2μm fine powder and small specific surface area.

2. Ball mill

The ball mill with classifier process is a process solution strongly recommended by the world’s advanced powder technology companies and widely adopted by famous European and American powder companies. It can be used to produce heavy calcium carbonate products with particle sizes of d97=5μm, 10μm, 16μm, 45μm, etc.

However, the heavy calcium carbonate powder products produced by the ball mill plus classifier process have problems such as excessive volume fraction of 2μm fine powder and excessive specific surface area, easy agglomeration of particles, poor product dispersion performance, and excessively high energy consumption per ton of product.

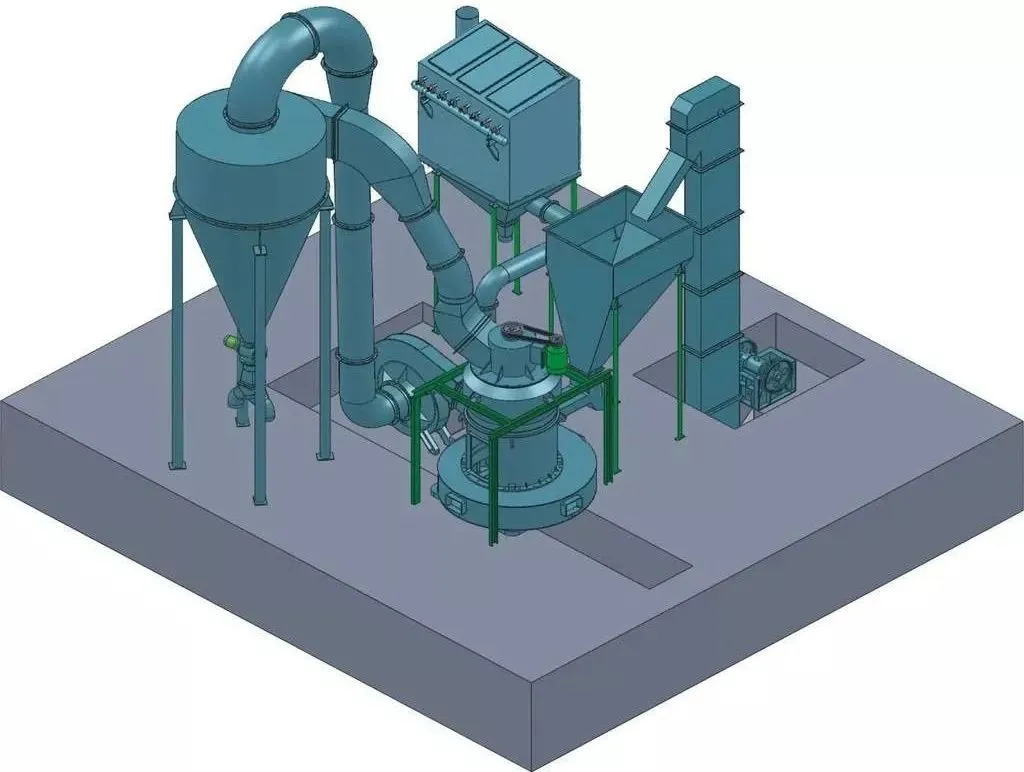

3. Vertical mill

Vertical mill uses the relative movement of the grinding roller and the grinding disc to crush the material bed. Vertical mill + secondary classification, tertiary classification dry process is one of the main advances in the fine processing technology of heavy calcium carbonate powder in recent years.

Using vertical mill, ordinary heavy calcium carbonate of 325-800 mesh can be directly processed, and some 325-800 mesh products can be graded twice or three times to produce medium- and high-grade fine powder of 1000-2500 mesh. The graded products can also be finely ground by wet mill or airflow mill to produce ultrafine powder of 2500-6500 mesh to meet high-end needs.