What is hard carbon?

Hard carbon refers to carbon materials that are difficult to graphitize above 2500°C. It gets its name from its high mechanical hardness. Hard carbon is generally made through heat treatment at 500–1200°C. Sources include resin carbon (phenolic, epoxy, polyfurfuryl alcohol), pyrolytic carbon (PVA, PVC, PVDF, PAN), carbon black, and biomass carbon.

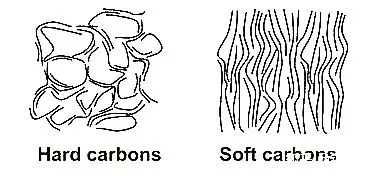

Examples of biomass carbon are glucose and cellulose. Hard carbon has a disordered structure and large interplanar spacing of 0.37–0.40 nm. This spacing supports Li⁺ insertion and extraction, leading to high specific capacity (up to 350–400 mAh/g). It shows good compatibility with PC-based electrolytes.

However, the initial irreversible capacity is high. It also suffers from issues like voltage hysteresis. Currently, hard carbon is used directly as an anode material. It can also be blended with graphite to improve fast-charging performance.

What is soft carbon?

Soft carbon refers to carbon materials that are easy to graphitize above 2500°C.

Examples include needle coke, petroleum coke, carbon fiber, and carbon microspheres.

Its graphitization degree is low, but layer alignment is better than that of hard carbon.

The interplanar spacing is about 0.34–0.35 nm.

This is larger than that of ideal graphite. Soft carbon offers good rate performance.

However, its specific capacity is lower (250–300 mAh/g), and the output voltage is also low.

It lacks a clear charge-discharge plateau. Soft carbon is rarely used directly as an anode material. Instead, it serves as a raw material for artificial graphite. It is also used as a coating to improve conductivity and kinetics.

Schematic Diagram of Hard Carbon and Soft Carbon Micro-structures

According to authoritative data, global anode material shipments reached 1.789 million tons in 2023. China contributed 1.667 million tons, making up 93.2% of the global total.

Over 90% of anode materials are produced in China. By product structure, artificial graphite is dominant, accounting for nearly 80%. Natural graphite makes up about 20%. Other anode materials represent only a small share.

Epic Powder is a trusted name in advanced powder processing solutions. With decades of experience and European core technology, we specialize in jet mills, classifiers, and complete systems for high-precision particle control. Our products are widely used in the battery, chemical, mineral, and pharmaceutical industries, serving clients across the globe with reliable quality and customized service.