In the automotive industry, materials with high impact resistance are commonly used. They are in car bodies and chassis to withstand collisions and compression. Polypropylene plastics filled with talcum powder can enhance the material’s bending performance but reduce its impact resistance to varying degrees. The quality of it significantly affects the impact resistance of the filled material. Generally, the silica (SiO₂) content and fineness of it have a greater influence on the material’s impact resistance. This article compares the impact resistance of products filled with talcum powder under different silica content and mesh size gradients.

Experiments

Three types of talcum powder with the same fineness but different silica contents were blended. Their polypropylene is at a 20% powder filling rate to prepare the samples. The samples were then processed through injection molding to obtain three sets of talcum powder-filled specimens with varying silica contents. After testing their impact resistance, the following results were obtained.

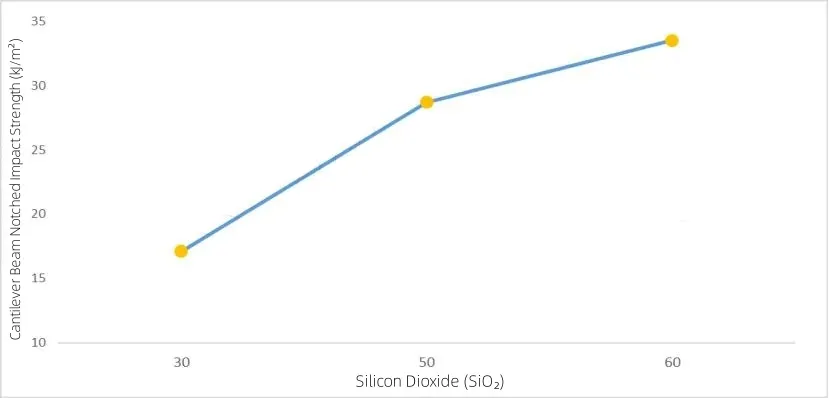

Figure 1 Impact resistance of products under different silica levels

Figure 1 shows that as silica levels increase, the impact resistance of the sample also increases accordingly. The higher the silica level, the higher the purity of the talc, the fewer impurities, the better the quality of the talc, and the less impact the impact performance will have on other associated mineral impurities, thereby improving the impact resistance of the sample.

Three types of talcum powder with the same silica content but different fineness levels were blended with polypropylene at a 20% powder filling rate to prepare the samples. These samples were then processed through injection molding to produce three sets of talcum powder-filled specimens with varying fineness levels. After testing their impact resistance, the following results were obtained.

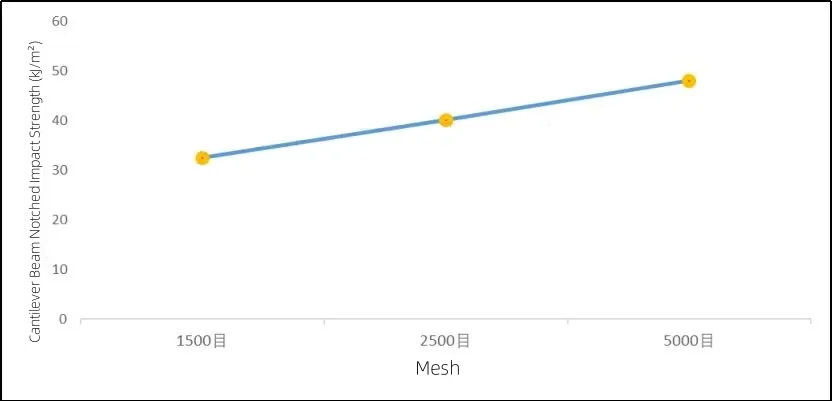

Figure 2 Impact resistance of products at different fineness

From Figure 2, the higher the mesh number of the product, the better its impact resistance. And this is when they are under the same silica content. This is because a higher mesh number corresponds to smaller talcum powder particles, resulting in a larger specific surface area. With more contact points between the powder and the resin, external forces generate more cracks and stress points. It enhances the material’s impact resistance.

In conclusion:

Through these two comparative experiments, we can conclude that for materials filled with talcum powder, both higher fineness and higher silica content contribute to improved impact resistance.

For products with higher performance requirements, increasing the mesh size of talcum powder and silica content can enhance the material’s impact resistance.

For products with a focus on cost-effectiveness, adjusting the silica content and fineness of the filler can help reduce costs while maintaining efficiency.

At Epic Powder, we offer a wide range of equipment models and tailor solutions to meet your specific needs.

Contact us today for a free consultation and customized solutions! Our expert team is dedicated to providing high-quality products and services to maximize the value of your powder processing.

Epic Powder—Your Trusted Powder Processing Expert!