Dry Grinding

For many products in our daily life requires grinding process. From breakfast cereals to cold medicine to paint and cement, grinding is a key step in bringing products to the market in the right form.

When the material enters machine, it is milled at high speed, which increases the evaporation surface area, has a large drying capacity, significant energy saving, high thermal efficiency of more than 70%.

The quality of dried products is uniform, the maximum dehydration capacity can reach 2t/h, product modification can also be carried out at the same time.

Negative pressure, dust-free, operation is simple, maintenance cost is low, variety of automatic protection functions and high reliability.

EPIC Powder can provide dry ultrafine grinding equipmentsuitable for various materials

Impact mill

High eficiency, has two miling effects of impact and grind, large miling ratio, simple structure, stable operation,suitable for milling medium-soft hard materials.

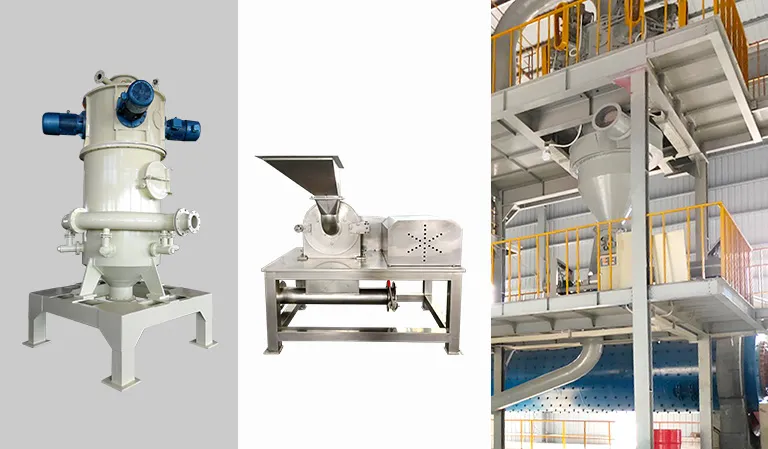

Jet mill

Uses the high speed turbulence airflow generated by compressed air or superheated steam as miling power. impactextrusion, friction and shear between the particles or between the particles and the fixed plate occur, so as to achievemilling.

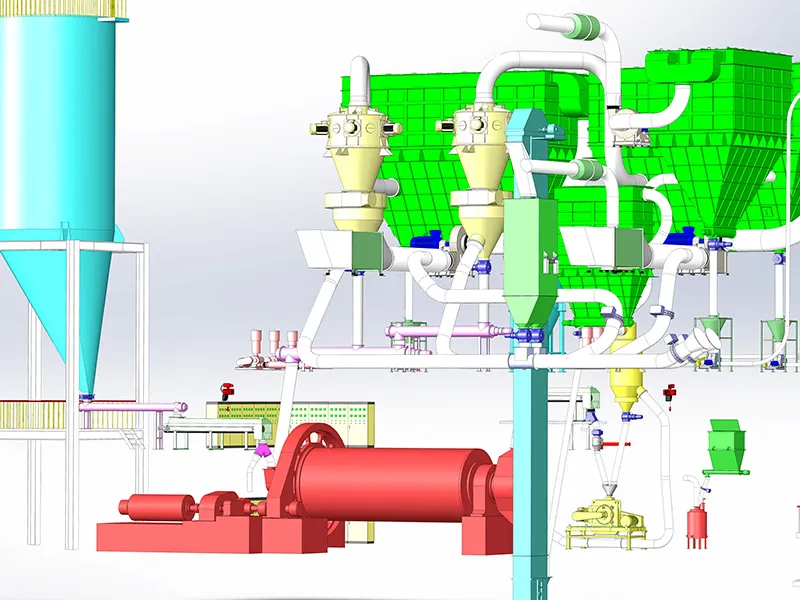

Ball mill + Classifying

The ball mill and classification production line refers to a complete set of milling system composed of Ball mil,cyclone, dust collector and fan.

Fluidized Bed Opposed Air Jet Mill

Suitable for grinding materials with high hardness, high purity and high added value.

Air Classifying Mill

Air classifier is ideal for fine powders of ceramics, abrasives, glass, minerals, and polymers.

Ball Mill and Air Classifier Production Line

Cooperate with the classifier to produce products of multiple particle sizes at the same time

Pin Mill

Widely used in chemical, inorganic salt, medicine, food, pigments, dyes, pesticides, battery materials, minerals, refractory materials and other industries.

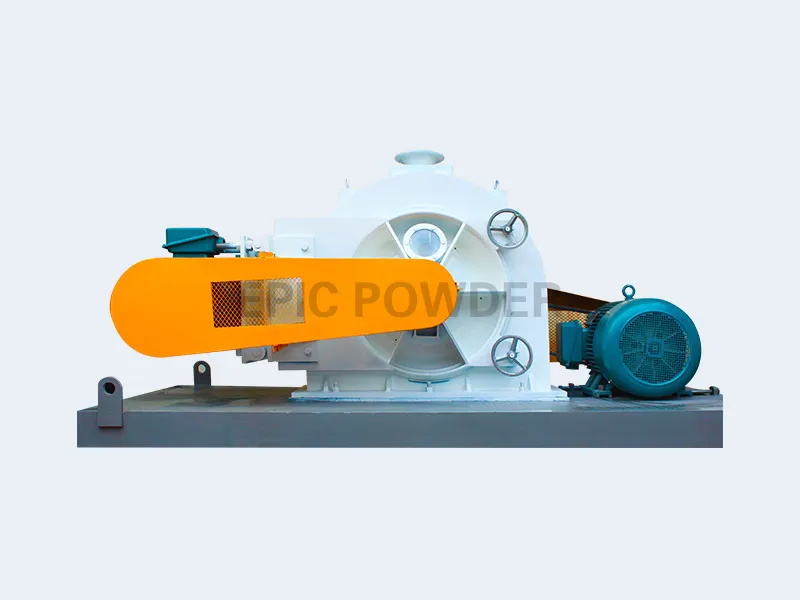

Multi-Rotor Mill

Surface modification of mineral powder is an inevitable product of the development of modern high-tech and new materials.

Vibration Mill

Ring Roller Mill

We Has Helped Them Solve the Problem

Production Line of Lithium Iron Phosphate for an Electric Vehicle Company in Huizhou

The company is a Chinese car manufacturer and one of the world’s second-largest producers of rechargeable batteries. As one of the earliest Chinese enterprises engaged in the manufacture of new energy materials, it possesses strong technical capabilities and significant influence in the industry. The company has maintained a successful partnership with Epic Powder. During its

A New Material Company in Zhejiang: Metal powder grinding equipment

The customer is a large domestic enterprise. To expand production capacity and improve efficiency, they needed grinding equipment with reliable performance, stable operation, and high yield. After investigation, they found that the grinding mills provided by Epic were more in line with the enterprise’s expected research outcomes. They also reviewed Epic’s experience and reputation

Silica soil drying and dispersing modification production line of a mineral products company in Jiangsu

This mineral company has the mining right. Also the mineral products have special physical and chemical indexes, which is difficult to process. The whole process flow is complicated and has high processing cost. Recommended by peers, it purchased two sets of drying and shattering-modified mechanical pulverizer production lines, and now the company has become a

Air Classifying production line of carbon microspheres in a chemical plant in Hubei

In recent years, the new energy industry has developed rapidly. This customer seized the opportunity to expand carbon microspheres production. Epic’s abundant cases in the new energy industry attracted the customer. Before purchasing the equipment, this customer visited Epic Powder‘s factory for two inspections and then finished material tests. The results were quite satisfactory. Epic

A ball milling and modification production line in a calcium carbonate factory in Iran

This customer, a prominent non-metallic ore processing enterprise in Iran, sought a new coating modification process. After exploring various options, he discovered Epic’s extensive experience in ultrafine processing and advanced modification of non-metallic ores. After two successful tests, he decided to purchase two sets of ball-milling classification and modification equipment to process calcium carbonate. Raw

Milk powder grinding production line of a company in Menggu

This customer is a well-known milk enterprise in China. During the launch of their freeze-dried milk powder project, they faced issues such as material sticking after heating and weight inconsistencies. Through local pharmaceutical companies, they discovered Epic‘s ultra-micro grinding technology for health products. After thorough investigation, experimentation, and structural optimization, Epic successfully resolved