As plastic modifiers, inorganic mineral powders possess a series of unique physical and chemical properties. They are high specific surface area, good thermal stability, and mechanical strength. In recent years, inorganic mineral powders have made significant contributions. They improve the performance of plastics and have promoted the development of the plastics industry.

1. Types of Inorganic Mineral Powders

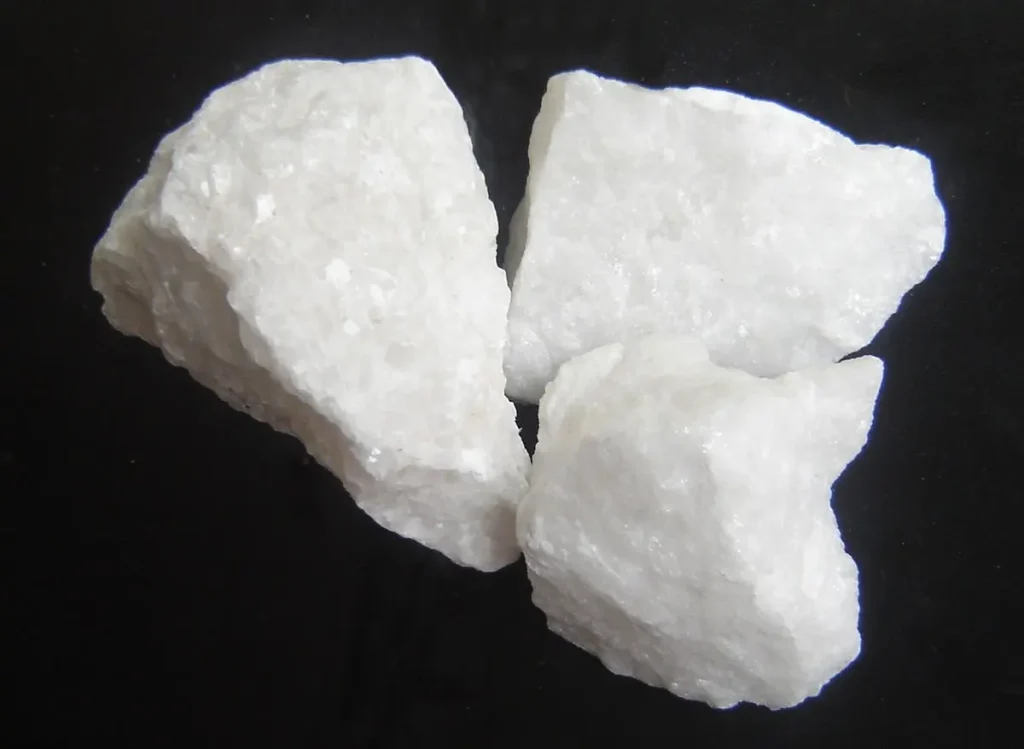

(1) Calcium Carbonate

Calcium carbonate is the earliest and most widely used inorganic filler material in plastics. It has excellent whiteness, stable chemical properties, and low oil absorption. By adding calcium carbonate, the hardness, dimensional stability, and processability of plastics can be improved. This also significantly reduces production costs.

Taking polyethylene (PE) and polypropylene (PP) as examples, the addition of calcium carbonate improves the tensile strength and flexural modulus of these two plastics, and enhances their heat deformation temperature. It’s worth mentioning that ultrafine calcium carbonate can also be used to manufacture high-performance plastics. It provides the materials with better mechanical and optical properties.

(2) Talc

Talc not only has excellent lubricity but also exhibits good heat resistance and electrical insulation. Due to the flaky structure and high diameter-to-thickness ratio of talc, the rigidity and hardness of the material can be significantly enhanced. Additionally, talc possesses properties such as heat resistance, thermal stability, lubricity, and dispersibility. This makes it applicable in a wide range of fields, making it an indispensable material in various industries.

(3) Kaolin

Kaolin is highly valued for its excellent whiteness, stable chemical properties, and good electrical insulation. Its unique flaky structure provides excellent filling and reinforcing effects. In the field of plastics, kaolin’s application value is primarily seen in its filling and reinforcing functions. Because of its stable chemical properties and excellent dispersibility, kaolin has been widely used in various plastics. For example, there’re polyvinyl chloride (PVC) and polyethylene (PE). The addition of kaolin can significantly improve the mechanical strength, wear resistance, and thermal stability of plastics. At the same time, it can also help reduce production costs. In some high-performance plastics, kaolin is even used as a flame retardant and antistatic additive.

(4) Mica Powder

Mica not only has excellent electrical insulation, heat resistance, and corrosion resistance, but also has a light transmittance. It exceeds that of other inorganic powders, along with the ability to block infrared rays. Therefore, it has been widely used in greenhouse films. As an important inorganic mineral filler, mica powder has played a significant role in various fields, such as plastics, due to its excellent physical and chemical properties.

(5) Wollastonite

Wollastonite in nature is mostly found as fibrous, radial, feathery, or blocky aggregates, with the most common forms being fibrous or needle-like structures. In the plastics industry, its fine particles are evenly mixed and added to the plastic matrix to effectively improve the mechanical properties of the plastic, enhancing its mechanical strength and thermal stability. At the same time, wollastonite also helps improve the wear resistance of the material. As a white filler, it gives the product a better visual effect and a more aesthetically pleasing appearance.

(6) Nano-Mineral Powder

With the continuous advancement of nanotechnology, nano-scale inorganic mineral powders have shown great potential in plastic modification. Nano-mineral powders have a large specific surface area, surface energy, and other properties, and offer unique advantages in the field of plastic modification. For example, nano-calcium carbonate can be used as a filler in rubber and plastic products to improve heat resistance, wear resistance, dimensional stability, rigidity, and processability, while effectively reducing costs.

2. Functions and Mechanisms of Inorganic Mineral Powders in Plastics

(1) Enhanced Mechanical Properties of Plastics

When inorganic fillers are mixed into the plastic matrix, a multiphase composite structure is formed. Mineral powders are distributed in the plastic matrix as dispersed phases. Their hardness and modulus are much higher than those of plastics. When subjected to stress, these powders can share and disperse the stress, thereby improving the mechanical strength of the material. Due to their high hardness, inorganic mineral powders act as a skeleton in plastics, preventing crack initiation and expansion, which reduces the risk of deformation and rupture.

For example, after talcum powder is mixed into polypropylene (PP), the bending modulus and tensile strength increase, and the toughness is improved. The modification of inorganic mineral powders can significantly enhance the mechanical strength, hardness, and rigidity of plastics, optimize their overall mechanical properties, and make filled composite materials widely applicable in many fields.

(2) Improved Thermal Properties

Wollastonite powder has high thermal conductivity and good insulation properties, which can improve the thermal conductivity and chemical stability of plastics. Mica powder, due to its layered structure and heat resistance, is widely used to enhance the thermal conductivity, mechanical properties, and weather resistance of plastics.

Alumina also has good thermal conductivity and chemical stability. It is often used to improve the thermal conductivity and heat resistance of plastics. Boron nitride has high thermal conductivity and excellent electrical insulation properties, which can significantly improve the performance of plastics. However, due to its scarcity and high cost, it is mainly used in high-end applications.

(3) Improved Electrical Properties

In the fields of electronic appliances and communication equipment, there are strict requirements for the electrical insulation properties of plastics. Certain specific mineral powders, such as kaolin and mica, have excellent electrical insulation properties. Incorporating these powders into plastics can significantly enhance the insulation properties of the materials, making them ideal for manufacturing electrical insulation components. Additionally, by introducing mineral powders with good electrical conductivity (such as carbon black and carbon nanotubes), conductive plastics can be developed. These materials have a wide range of applications in antistatic and electromagnetic shielding fields.

(4) Reducing Material Costs

The cost of mineral powders is much lower than that of polymer resins. Therefore, by incorporating inorganic mineral powders into plastic materials, the production cost of plastic products can be effectively reduced. For example, adding calcium carbonate to common plastics such as PVC and PE not only reduces material costs but also improves their mechanical properties and processing characteristics. In large-scale industrial production, selecting the appropriate type and amount of fillers can reduce production costs to some extent, while maintaining or even improving the performance of plastics, thus enhancing the competitiveness of products in the market.

3. Specific Application Scenarios of Inorganic Mineral Powders in Plastics

(1) Automobile Industry

Lightweight plastic materials are widely used in the automobile industry to help achieve energy conservation and reduce emissions. Adding inorganic mineral powders to plastics can significantly enhance their mechanical properties and create lightweight plastic products, which is especially important in the automotive and aerospace fields.

For example, adding talcum powder or calcium carbonate to PP can improve the tensile strength and rigidity of the material while reducing its weight. The incorporation of these mineral powders can also enhance heat resistance and dimensional stability, meeting the application requirements of automotive parts in high-temperature environments. This improves creep resistance at high temperatures, reduces shrinkage, and results in better surface quality, more attractive appearance, and a more suitable feel.

(2) Building Materials

Inorganic mineral powders play an increasingly important role in the field of building materials. Because they have unique physical and chemical properties. In the production of PVC pipes and sheets, composite materials made by introducing kaolin can improve the tensile strength and flexural modulus of the materials, while also enhancing impact resistance and chemical corrosion resistance. For roads and infrastructure, limestone powder and other mineral powders are often used as fillers in asphalt mixtures to improve the strength and durability of the road surface. Through these modifications and optimizations, inorganic mineral powders can not only enhance the performance of building materials but also promote the development of green buildings, supporting the sustainable development goals of the construction industry.

(3) Electronics and Electrical

Plastic materials play a crucial role in the electronics and electrical industries, where they need to have excellent electrical insulation and thermal conductivity. Electrical insulation is a key characteristic of plastic materials, but it may need to be improved for high-demand applications. Kaolin and mica powder are commonly used inorganic mineral powders. When combined with plastic resins, they can increase resistivity and prevent electrical failures. Mica powder, with its high heat resistance, is ideal for high-temperature electronic packaging. Alumina and boron nitride are thermally conductive powders that, when mixed with plastic resins, improve thermal conductivity. These are widely used in electronic packaging, heat dissipation devices, automobile engines, and other applications.

(4) Inorganic Mineral Powders for Daily Consumer Goods

Inorganic mineral powders play a significant role in enhancing the properties of plastic products, improving their adaptability. Talc and mica powder are two commonly used inorganic mineral powders. In the production of household appliance shells, talc enhances toughness and prevents cracking. Mica powder improves heat resistance and maintains stable performance. Kaolin and calcium carbonate are essential in the manufacture of children’s toys. They improve mechanical strength, reduce the coefficient of friction, minimize wear, enhance processing performance, increase hardness, and ensure safety and durability.

For businesses with regular full-scale production, milling in-house can be a cost-effective option. EPIC Powder is expert at providing custom milling solutions for your industry.