Material Information

Powder materials are crucial in many industries, including pharmaceuticals, metallurgy, and additive manufacturing. These fine particles, sized from micrometers to millimeters, have unique properties. They are suitable for many applications. It is key to know the traits and behaviors of powders. This is vital for optimizing processes and getting the desired results.

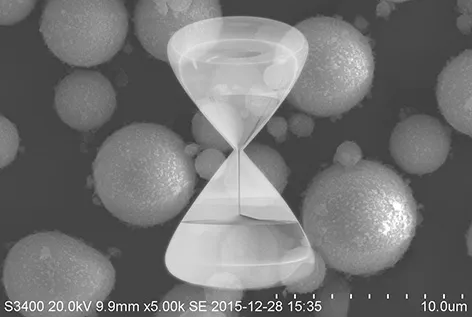

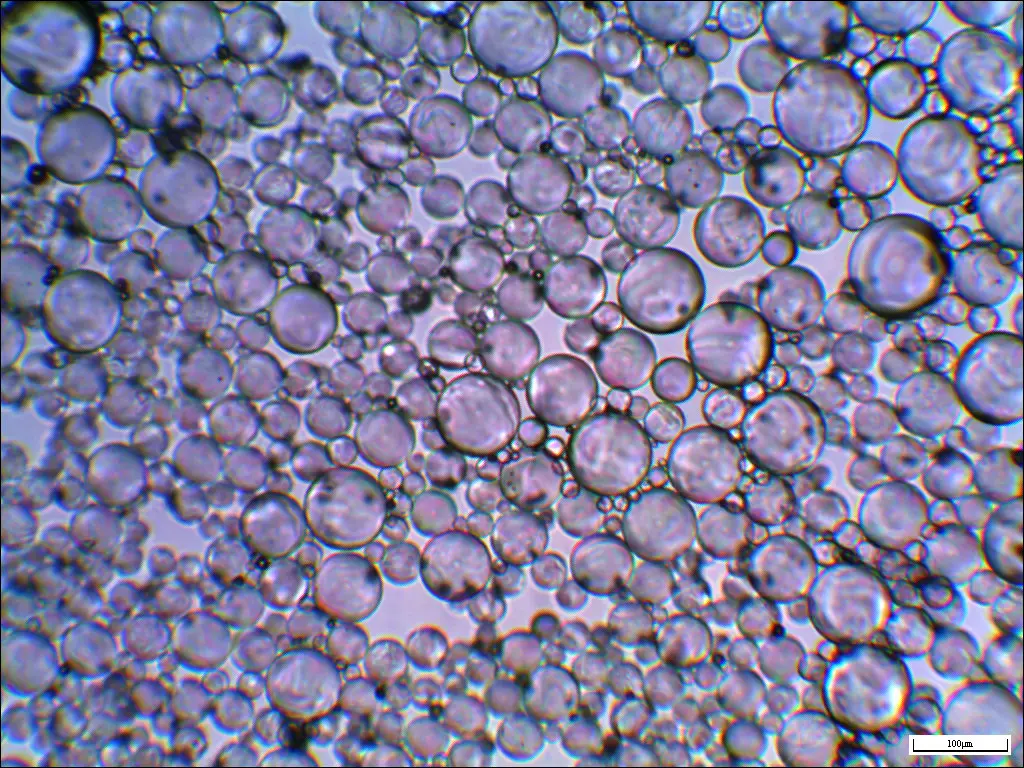

A key factor in powder material is its particle size and distribution. These factors significantly influence the flowability, packing density, and reactivity of the powders. In additive manufacturing, a narrow range of particle sizes can improve layer uniformity. This leads to better mechanical properties in the final product.

Another important aspect is the morphology of the particles. The shape and surface texture of powder materials can affect their behavior during processing. Spherical powders flow and pack better than irregularly shaped particles. So, they are ideal for 3D printing.

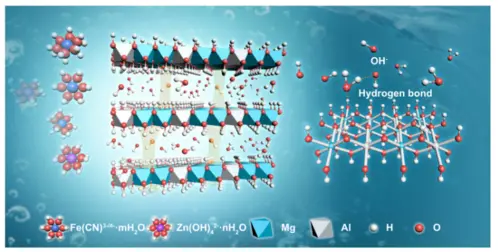

Also, the chemical composition of powder materials is critical in fields like pharmaceuticals. There, purity and consistency are vital. Manufacturers must ensure that powders meet strict quality standards. This is to guarantee the efficacy and safety of end products.

Lastly, it is vital to understand how to store and handle powder materials. This prevents contamination and degradation. Good techniques can keep powders intact. They will then work well in their intended uses.

In conclusion, powder material info includes many factors. These are particle size, morphology, chemical composition, and handling practices. A thorough grasp of these elements is vital for industries that use powder materials to innovate and improve their products.