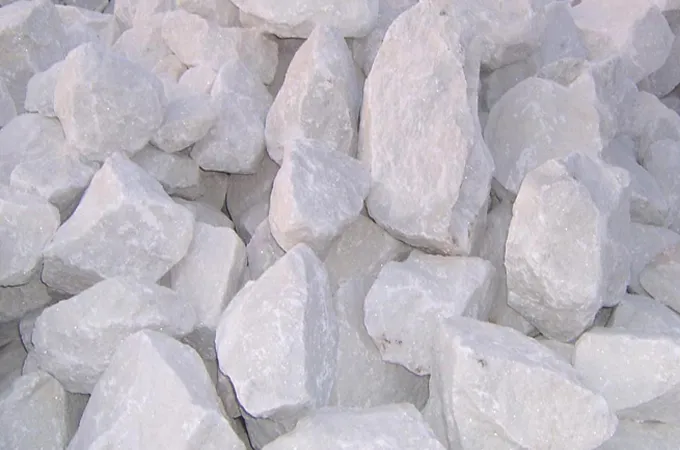

Eight Major Advantages of Modified Barium Sulfate in the Plastics Industry

The unique and excellent properties of barium sulfate make it widely used as a new functional modifier in plastics. Barium sulfate improves chemical resistance, heat resistance, and enhances the appearance of plastic products. It is used in PP, ABS, PA, PET resins for household shells, mechanical parts, auto parts, air conditioner panels, etc. Barium sulfate increases plastic density, […]

Eight Major Advantages of Modified Barium Sulfate in the Plastics Industry Read More »