How does the particle size distribution of powder affect the absorption rate of drugs?

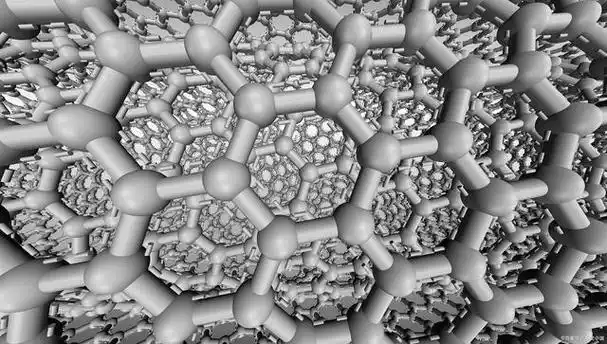

The influence of particle size distribution on drug absorption rate has many aspects. They’re mainly reflected in the following key points. Solubility and bio-availability Reducing particle size can significantly increase the surface area of drugs. So it can accelerate their dissolution rate in vivo. According to the Noyes Whitney equation, the dissolution rate is directly proportional to the […]

How does the particle size distribution of powder affect the absorption rate of drugs? Read More »