This article explores grinding with media and focuses on the main operational factors influencing mill efficiency: grinding media loading, grinding concentration, feeding speed, and graded sand return control.

I. Impact of Grinding Media Loading on the Mill

1. Loading System and Impact:

Material: The grinding media’s material significantly affects grinding efficiency and mill wear. Ideally, it should be wear-resistant, with low crushing and irregularity rates, and high cost performance. Effective grinding media minimizes wear and reduces labor intensity.

Media Ratio: The size and specification of grinding media should be appropriately matched. For instance, in ball mills, the ratio of steel balls of various diameters depends on below factors. Such as ore properties, particle size, and grinding fineness. Various methods exist for calculating ball ratios. But there is no unified academic consensus.

Media Filling Ball Ratio: The filling rate influences the grinding media’s lifting height and stratification. This impacts grinding efficiency. Different mills have varying filling rate requirements. A higher filling rate, within reason, generally enhances production capacity and effectiveness.

One-Time Loading Weight: This is determined by the mill’s filling rate and media type. The initial loading weight is crucial for mill load and efficiency, affecting unit consumption of grinding media. For newly installed mills, start with 80% of the maximum filling weight and add the remaining 20% after production stabilizes. For mills that have passed the running-in period, maintenance or relocation can be completed in one go.

2. Supplementary Media System and Its Impact

Specifications of Supplementary Media: The specifications and supplementary ratios of media are generally determined by screening the raw ore and evaluating its properties. Or it’s based on experience and adjusted according to actual needs. The appropriateness of the ratio of media of different specifications significantly impacts the grinding effect.

Quantity of Supplementary Media: The amount of media to add per ton of ore, including the quantity and weight of each media specification per ton of ore processed per shift, is determined based on unit consumption. This is typically estimated based on experience and grindability tests and then corrected and adjusted during production. Adding a reasonable and sufficient amount of media greatly affects grinding efficiency.

How to Add Media: The timing, duration, specifications, and quantities of media added each time should be managed to ensure appropriateness. The filling rate should not be too high or too low.

Checking Media Situation: When possible and necessary, check the media situation in the mill body. It is recommended to inspect the filling rate, proportion, crushing rate, and irregularity rate of the media each time the mill is opened. Adjustments should be made to ensure accuracy in media addition and cost calculation. If needed, empty the mill, clean and re-mix the media, and recalculate the unit consumption to ensure precise media addition and cost management.

3. Optimize the Loading and Replenishing Medium System

Mechanical Research: Conduct mechanical research on the crushing resistance of the ore, including determining its uniaxial compressive strength, elastic modulus, and Poisson’s ratio. This provides a mechanical basis for accurate loading and replenishing of balls.

Screening the Ore: Screen the ore to be ground (including new ore and returned sand) to determine the particle size composition and stage proportion. Calculate the maximum ball diameter and the diameter and proportion required for each group of ore.

Loading Balls: Based on the grinding purpose, consider the levels that need to be strengthened and those that do not require crushing. Adjust the loading to increase the crushing probability of the former and reduce the probability of the latter.

Testing Initial Loading Balls: For verification, if conditions permit, test the initial loading balls to ensure that the determined scheme is optimal.

II. The influence of Grinding Concentration on Grinding Mill

Grinding concentration, also known as slurry mass concentration, is usually expressed as the weight of ore (dry) in the mill as a percentage of the total slurry weight.

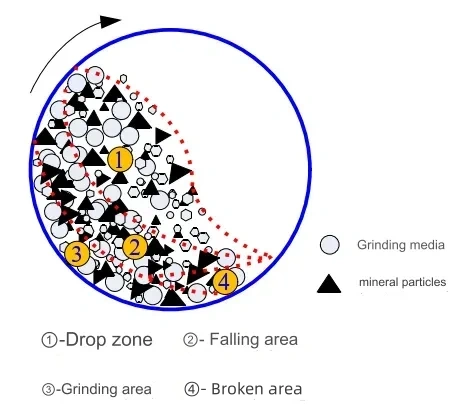

he thicker the slurry, the greater its viscosity, the lower its fluidity, and the slower it passes through the mill. In a thick slurry, the steel balls experience greater buoyancy, their effective specific gravity is slightly reduced, and the impact effect is slightly diminished. The thick slurry contains more solid mineral particles per unit volume, making it more likely for the ore to be impacted and ground by the steel balls.

The situation in a thin slurry is just the opposite. Under the same conditions, if the slurry is too thick, its fluidity becomes poor, or it may even lose fluidity, causing the grinding efficiency to drop rapidly. Conversely, if the slurry is too thin, the grinding cycle will be accelerated, the grinding time will be sharply shortened, and the grinding efficiency will also deteriorate significantly.

3. The influence of Feeding Speed on the Mill

Feeding speed refers to the amount of ore passing through the mill per unit of time. When the mill feeds less, not only is the productivity low, but phenomena such as empty grinding can occur, leading to serious equipment wear and over-crushing of the ore. Conversely, when the mill feeds more, it can quickly lead to swelling in the mill, resulting in inevitable indigestion and low operating efficiency.

For the mill to operate effectively, an appropriate feeding speed should be maintained to ensure that a suitable amount of ore is kept in the mill for grinding. Therefore, feeding must be continuous and uniform, avoiding fluctuations that can affect grinding, classification, and ultimately separation. The more stable the feeding amount of the mill in the concentrator, the better. However, due to the properties of certain ores, maintaining a suitable feeding speed can be challenging.

4. The influence of Graded Return Sand on the Mill

The amount of return sand and its moisture content, as well as the particle size distribution within the return sand, directly affect the grinding concentration and the feed speed of the mill. These factors significantly influence the grinding efficiency of the mill.