The ball milling and classifying production line is commonly used in various industries, including mining, metallurgy, chemicals, and building materials. This article introduces the basic concept of a ball milling and classifying production line, explores its applications in non-metallic minerals, and provides guidance on selecting the right production line for your needs.

I. What is a Ball Milling and Classifying Production Line?

This production line is a powder-making system that consists of two key components: a ball mill and an airflow classifier. The ball mill grinds raw materials to produce powder particles, while the airflow classifier separates the powder based on particle size using airflow and centrifugal force. This process yields a final product within the desired particle size range.

II. Application of Ball Milling and Classifying Production Lines in Non-Metallic Minerals

In the non-metallic minerals sector, ball milling and classifying production lines are widely used for ultra-fine grinding. Some examples include:

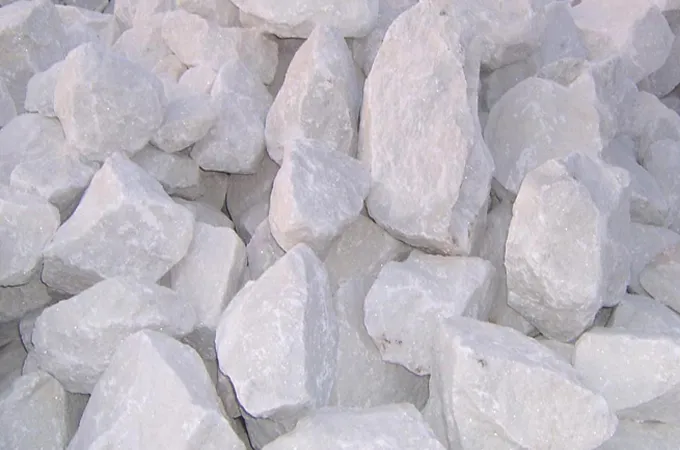

Heavy Calcium Carbonate: Heavy calcium carbonate is a fine powder with high whiteness and gloss, widely used in industries such as plastics, rubber, and paints.

Titanium Dioxide: Titanium dioxide is a white pigment commonly used as a filler and colorant in paints, plastics, paper, and other industries.

Abrasives: Ball milling and classifying production lines are also employed in the manufacture of abrasives, such as cutting, grinding, and polishing tools, which are used in metal processing, glass processing, and other industries.

III. Which Non-Metallic Minerals Are Suitable for Ultra-Fine Grinding with Ball Milling and Classifying Production Lines?

Ball milling and classifying production lines are ideal for ultra-fine grinding of the following types of non-metallic minerals:

Materials with Lower Hardness: If raw materials have high hardness, a higher-power ball mill is required, increasing production costs. Therefore, the ball milling and classifying production line is better suited for materials with lower hardness, such as heavy calcium carbonate and talcum powder.

Materials Requiring High Precision: This production line can produce fine powders with a relatively uniform particle size, making it suitable for materials that demand high precision, such as bauxite and titanium dioxide.

Materials Requiring High Quality: Since the ball milling and classifying production line can separate fine particles through airflow classification, high-quality products are achievable, such as titanium dioxide and aluminum borate.

Classifier

IV. How to Choose a Ball Milling and Classifying Production Line That Suits Your Needs

When selecting a ball milling and classifying production line, consider the following factors:

Raw Material Characteristics: Different raw materials require different production lines. For example, raw materials with higher hardness require a more powerful ball mill, while those requiring higher fineness demand a finer milling and grading production line.

Production Capacity: To choose the right production line, consider your production needs, including volume and cycle times. Determine the specifications, quantity, and configuration of the required equipment.

Technical Expertise: When selecting a supplier, ensure their technical expertise, product quality, and after-sales service meet your needs. This will ensure the equipment’s stability and long-term operational efficiency.

Cost Control: While choosing a production line, consider the total cost of ownership, including the purchase price, operating expenses, and maintenance costs. Minimizing costs while ensuring equipment quality and production efficiency will help maximize your company’s economic benefits.

Future Development Plans: Consider your future expansion plans when selecting a production line. Estimate future market demand and the need for increased production capacity to ensure the equipment is adaptable and scalable.

In short, choosing the right production line requires a comprehensive evaluation of several factors. By focusing on equipment quality, production efficiency, and cost control, you can achieve optimal production results.

Conclusion

In summary, choosing the right ball milling and classifying production line requires a comprehensive evaluation of various factors. Ensuring equipment quality, production efficiency, and cost control will help you achieve optimal production goals.