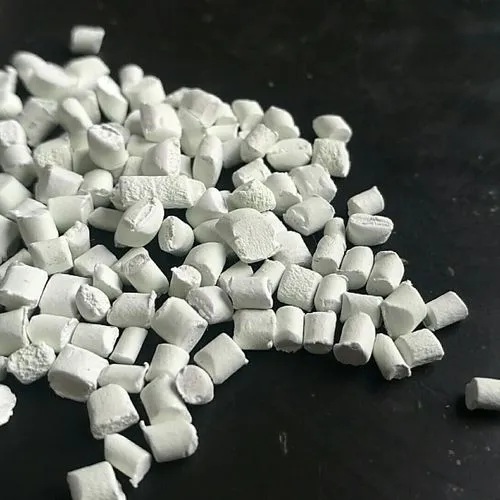

Masterbatch

Calcium-based masterbatch is a commonly used plastic filling material, composed of chemical additive, carrier resin and dispersant. Granular materials obtained by extruders and other equipments through processing of metering, mixing, melting, extruding and pelletizing, are usually called masterbatch. Masterbatch is composed of carrier resin, various fillers and various additives.

Calcium-based masterbatch is one of the most popular plastic fillers, accounting for about half of the total fillers in the plastics industry. With lower cost of calcium carbonate than base resin, production cost is greatly reduced accordingly. Moreover, the addition of calcium-based masterbatch enhances the properties of plastic products, such as increasing the tensile modulus and strength, and improving the surface smoothness of the products.

Application in hollow board

Hollow board is a new type of material which is light in weight, anti-aging, corrosion-resistant, waterproof and moisture-proof, green and environmentally friendly, rich in colors, safe and hygienic etc. Combining many years of technical research and development and production experience, we produce hollow boards based on calcium-based masterbatch, with low prices, stable performance and diversified application scenarios. According to the needs of customers in different industries, we can flexibly design and customize hollow boards for usage of packaging, turnover, protection and display.

Calcium-based masterbatch hollow board has the characteristics of light weight, compression resistance, sound insulation and heat insulation, and is often used in construction, furniture, packaging and other fields. Due to advantages of low cost, environmental protection and easy processing, calcium-based masterbatch hollow board has become one of the popular products in recent market.

Application in auto parts

Calcium-based masterbatch can be used in manufacturing auto parts such as car bodies, dashboards, door panels, bumpers and engine hoods. It can improve the hardness and durability of these parts, reduce production costs, improve production efficiency, and improve their processing performance, mechanical properties and thermal properties.

For example, adding filler masterbatch can increase the melting point, heat deformation temperature and heat resistance of plastics, thereby improving the service life and safety of automotive parts.

Application in home appliance housing

The application of calcium-based masterbatch in home appliances can be seen everywhere. Calcium-based masterbatch materials are used in televisions, air conditioner shells, washing machines, microwave ovens, fans and stereos to varying degrees.

The addition of calcium-based masterbatch can ensure color uniformity and stability of the appliance housing and improve its performance.