As the main building decoration material, about 70% of the marble resources are converted into waste during mining, cutting and polishing, causing serious waste of resources and environmental pollution. The issue of comprehensive utilization of marble tailing and waste residue are is imminent.

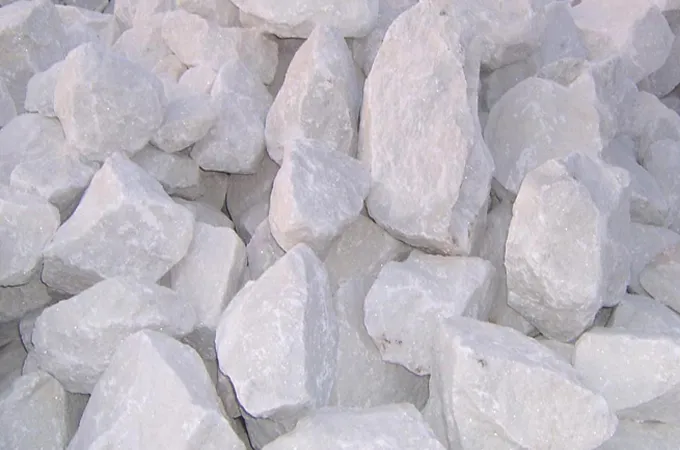

Marble tailing is non-metallic mineral, its main component is calcium carbonate. At present, the main ways of comprehensive utilization of marble tailing and waste residue are as below:

For the production of calcium carbonate:

Wash the marble tailing with water, after dehydrated and screened, the marble tailing with particle sizes bigger than 50mm can be used as raw material for production of light calcium carbonate or heavy calcium carbonate.

The main component of marble waste is calcium carbonate, it can be used to produce light calcium carbonate with process of conventional calcination-digestion-carbonization. By adopting hydrothermal treatment process in alkaline solution, the concentration of colored impurity ions of marble powders can be reduced through procedure of dissolution-recrystallization, high-whiteness calcium carbonate powders are produced, which are expected to be applied to the large-scale utilization of marble waste.

For the production of stone-like coating:

Stone-like coating is mainly composed of natural waste stone powder, binder and additives. According to different ratio of particle sizes and color, it can be made into stone-like coating to meet different requirements. Marble tailing and waste residue can be ground to a certain fineness and used as filler for stone-like coating, with the addition ratio being as high as 60% to 70%. This is an efficient way to treat waste residue and is widely used.

For the production of artificial granite:

Artificial granite is a kind of synthetic stone. Its main raw materials are marble fragments and stone powder. Its production process is: with organic resin as binder,by vacuum stirring, high-pressure vibration molding and room temperature curing, artificial granite is correspondingly produced. Hezhou from Guangxi is rich in marble resource and is the largest production base of heavy calcium carbonate powder and artificial granite in our country. A green circular industrial chain of mining-natural stone-heavy calcium carbonate powder-artificial granite-coatings and plastics-waste slurry and waste residue recycling is formed there.

For the production of concrete:

Using waste marble as aggregate or partially replacing cement in concrete can improve the mechanical properties of concrete, which mainly include wear resistance, compressive strength and flexural strength. The proportion (relative to cement) is around 5% to 40%.

For the production of desulfurization agent:

The desulfurization method of producing desulfurization agent with waste marble powders is high-efficient and greatly reduces the production cost. However, this method has high requirement on the purity of the waste marble powders.

For the production of machine-made sand:

In recent years, the central and local governments have successively introduced a number of policies to encourage the use of tailing and wastewater to produce machine-made sand.

For the production of soil conditioners:

The alkalinity of marble waste can be used to neutralize the acidic soil without no damage to the soil. Using marble powder and rice husk ash as soil additives can improve soil expansion rate and expansion pressure.

For the production of composite materials:

Mixing a certain amount of marble waste with ceramics or polymer can produce composite materials. Choudhary uses marble waste powder to fill glass fiber. When 20 wt% marble powders are added , the flexural strength and flexural modulus of the composite material are significantly improved. NAYAK uses marble powders as secondary filler in glass polyester material system to produce wear-resistant hybrid composite material. Study shows that adding marble powder filler is helpful in reducing the wear rate of composite material and improving its wear resistance.

For the production of aragonite whiskers:

Luo Dongshan uses quicklime obtained by pre-treatment and calcination of tailing from a marble mine in Shimian County from Sichuan as raw material and uses magnesium chloride as crystalline control agent to prepare aragonite whiskers by carbonization method. At the temperature of 80°C with MgCl2 concentration of 0.2 mol/L, and quicklime dosage of 6 g/L, aragonite whiskers with length of 40-50μm, diameter of 2-3μm and aspect ratio of 13-18 can be produced.

Filter media for wastewater treatment:

There are many methods of chemical treatment commonly used in the treatment of industrial wastewater. Among them, the filtration neutralization method (suitable for when the acid concentration is not too high) has three types of filter medias: limestone, marble and dolomite. If there are factories nearby that need to treat acidic wastewater, select them as filter media is a good choice.